91

Small Parts & Assemblies

8

Instruments

9

Experiment Instrument

6

Al & PTFE Nuclear Irradiation Assembly

4

Surgical Instrument Holders

16

Very High Temp Research Device Components

2

Cancer Treatment Components

25

Small Projects of Note

44

Plastic Machining

3

Brachytherapy Applicator Modify

3

K-Wire Holders

8

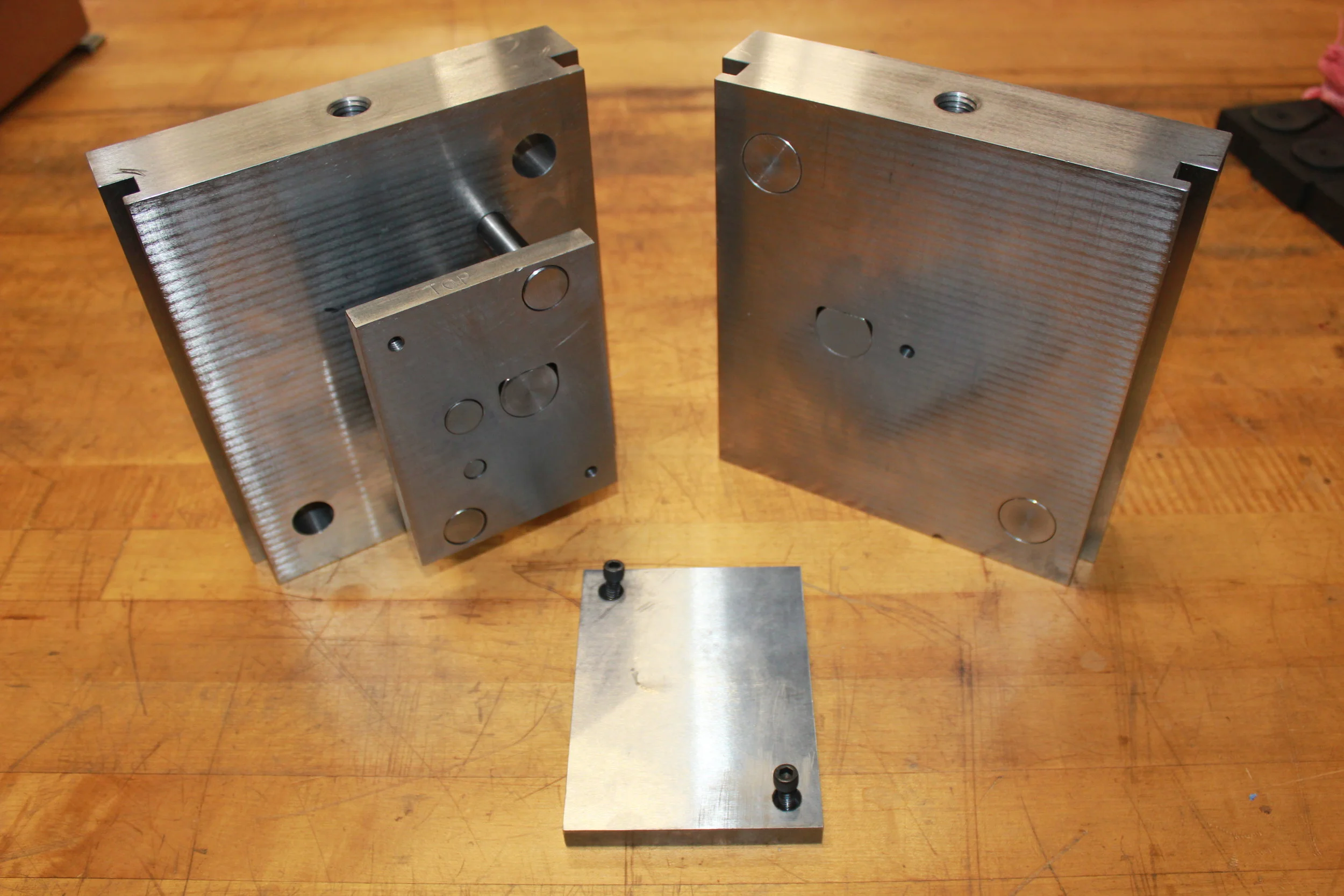

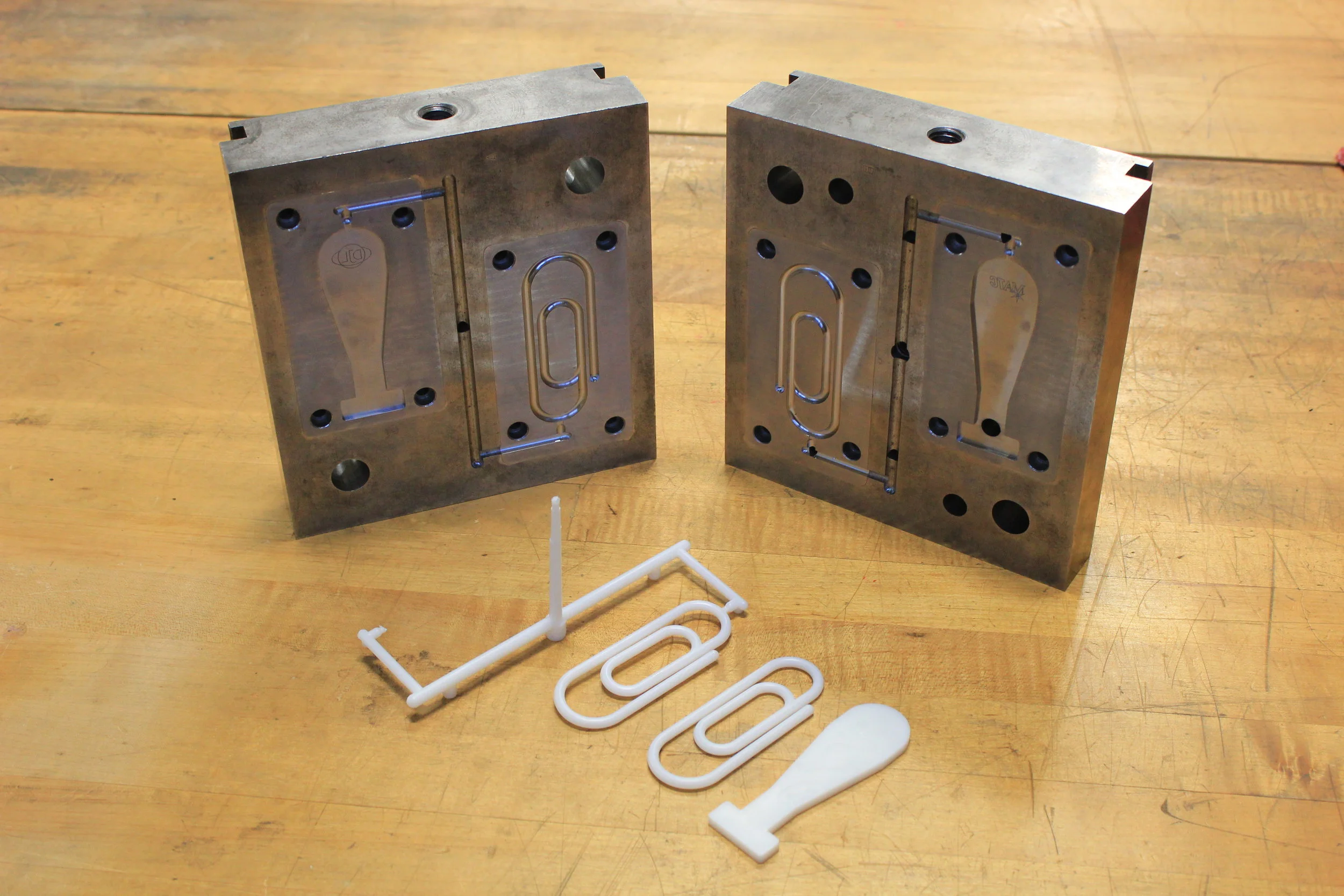

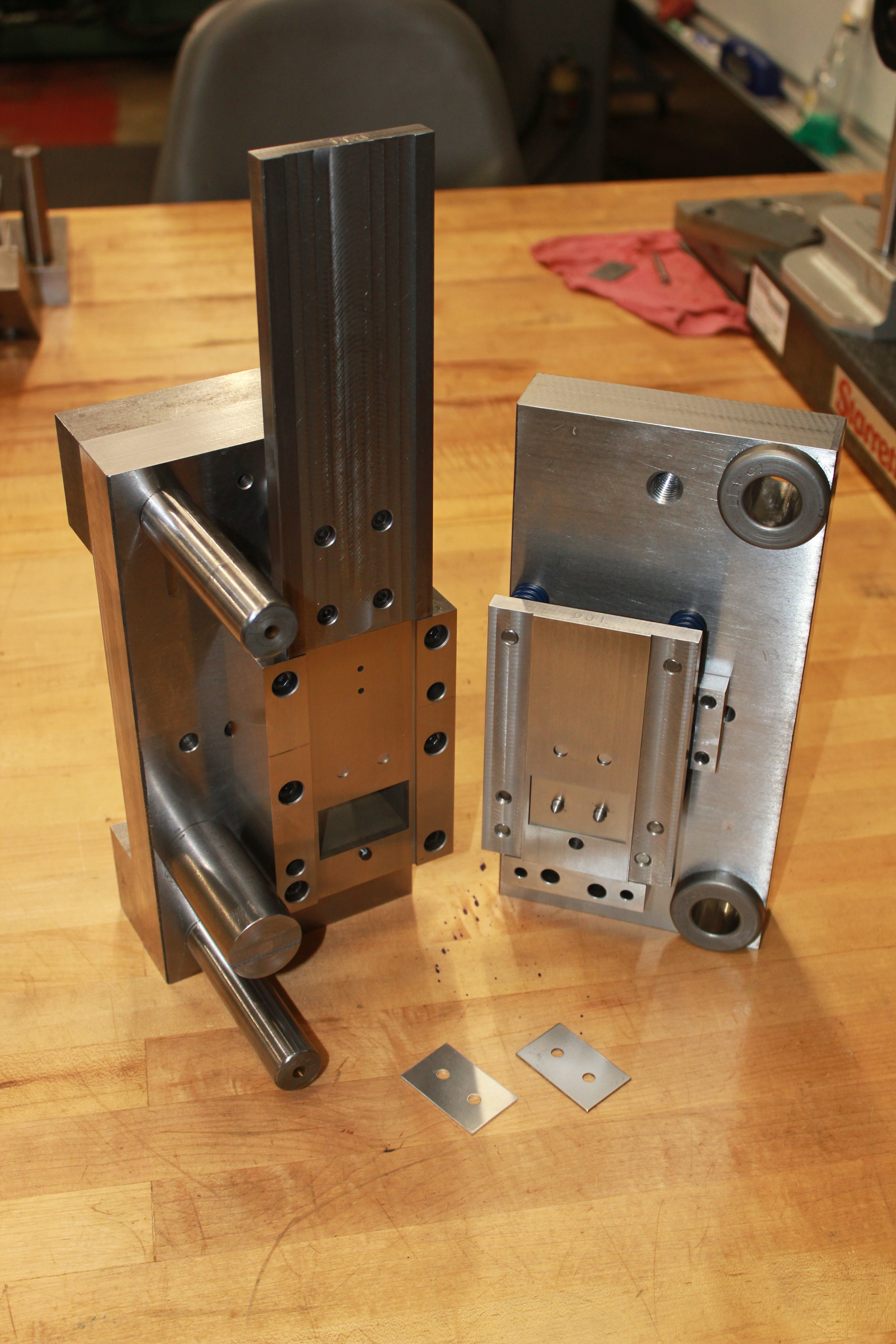

Tool & Die, Mold Making

6

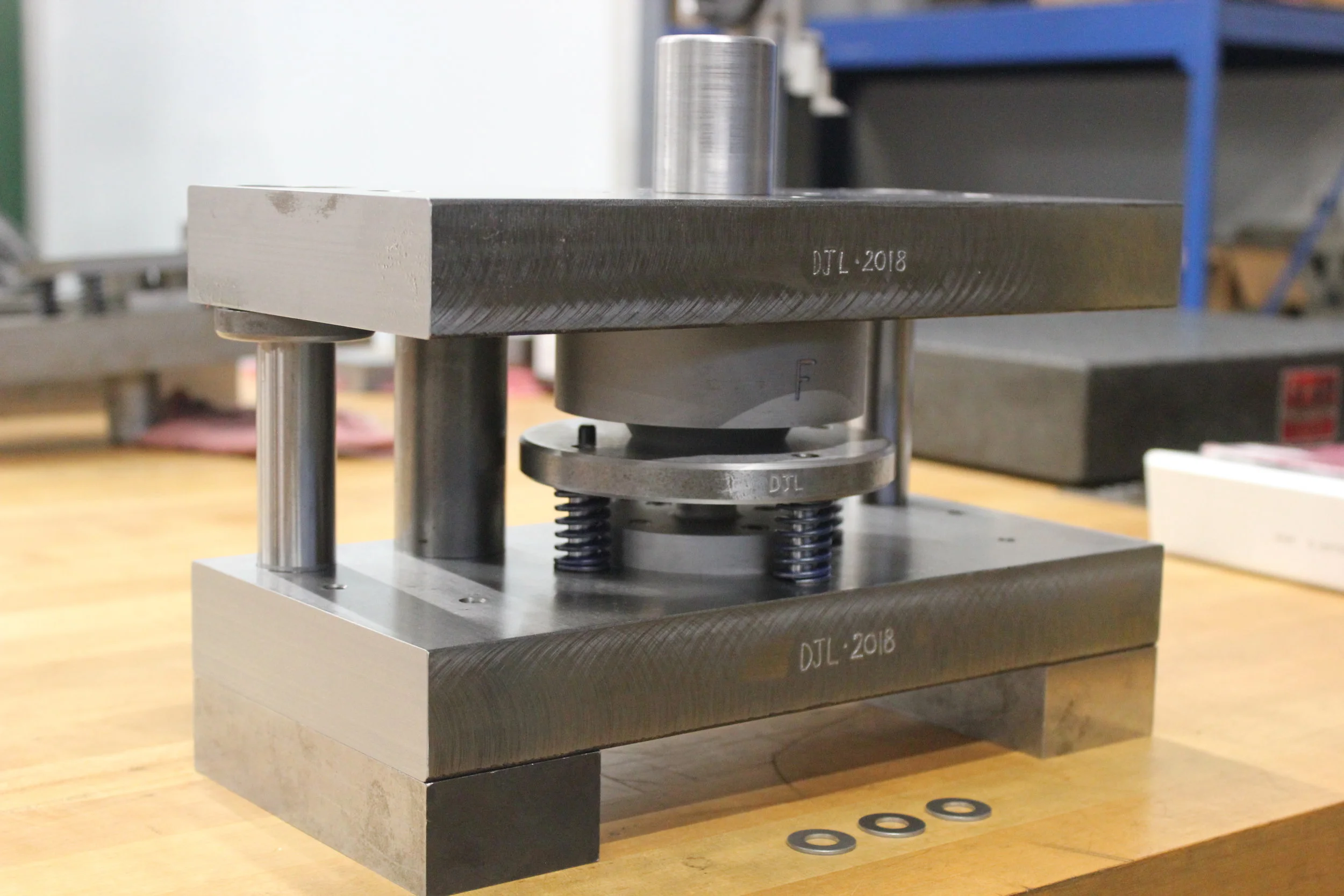

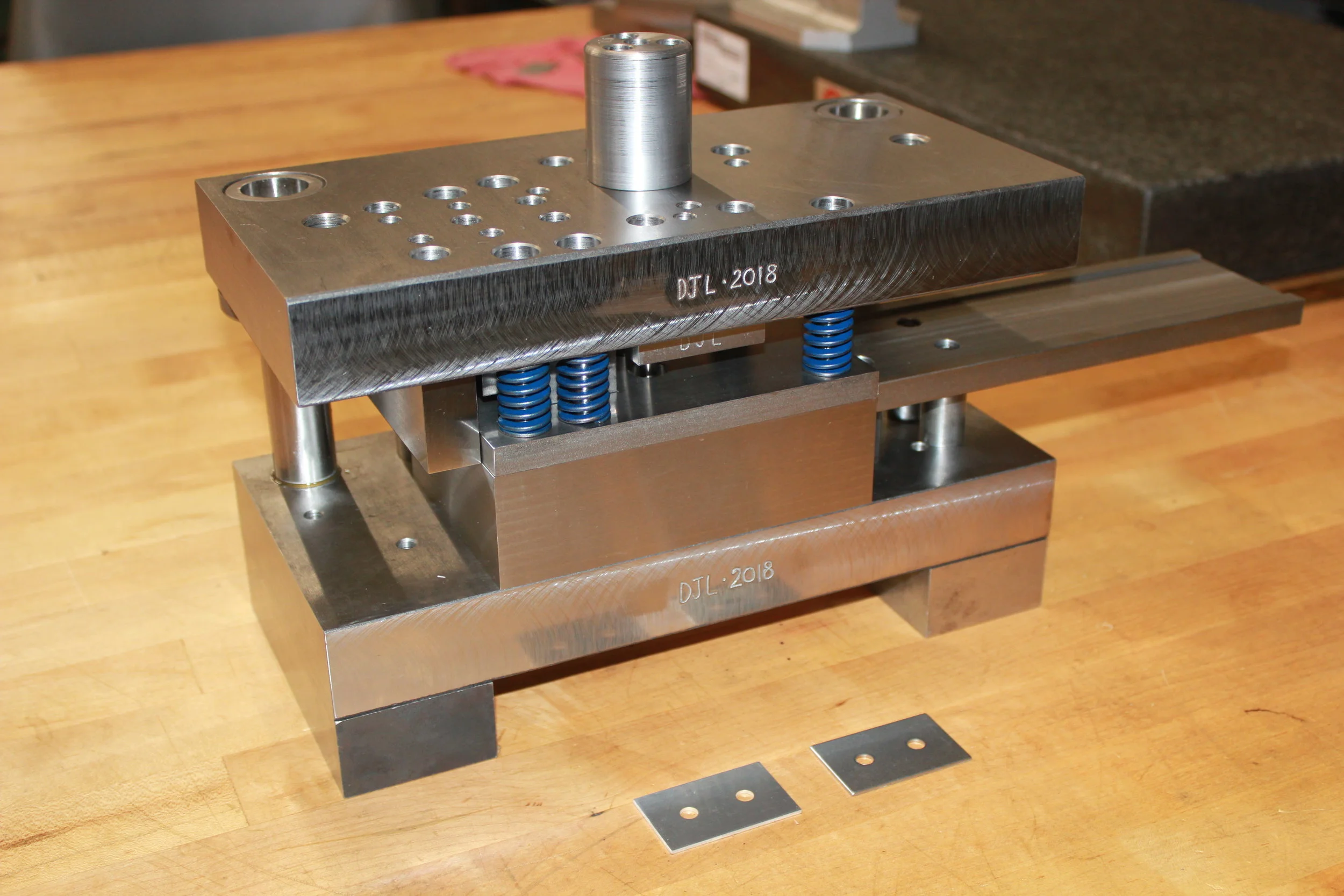

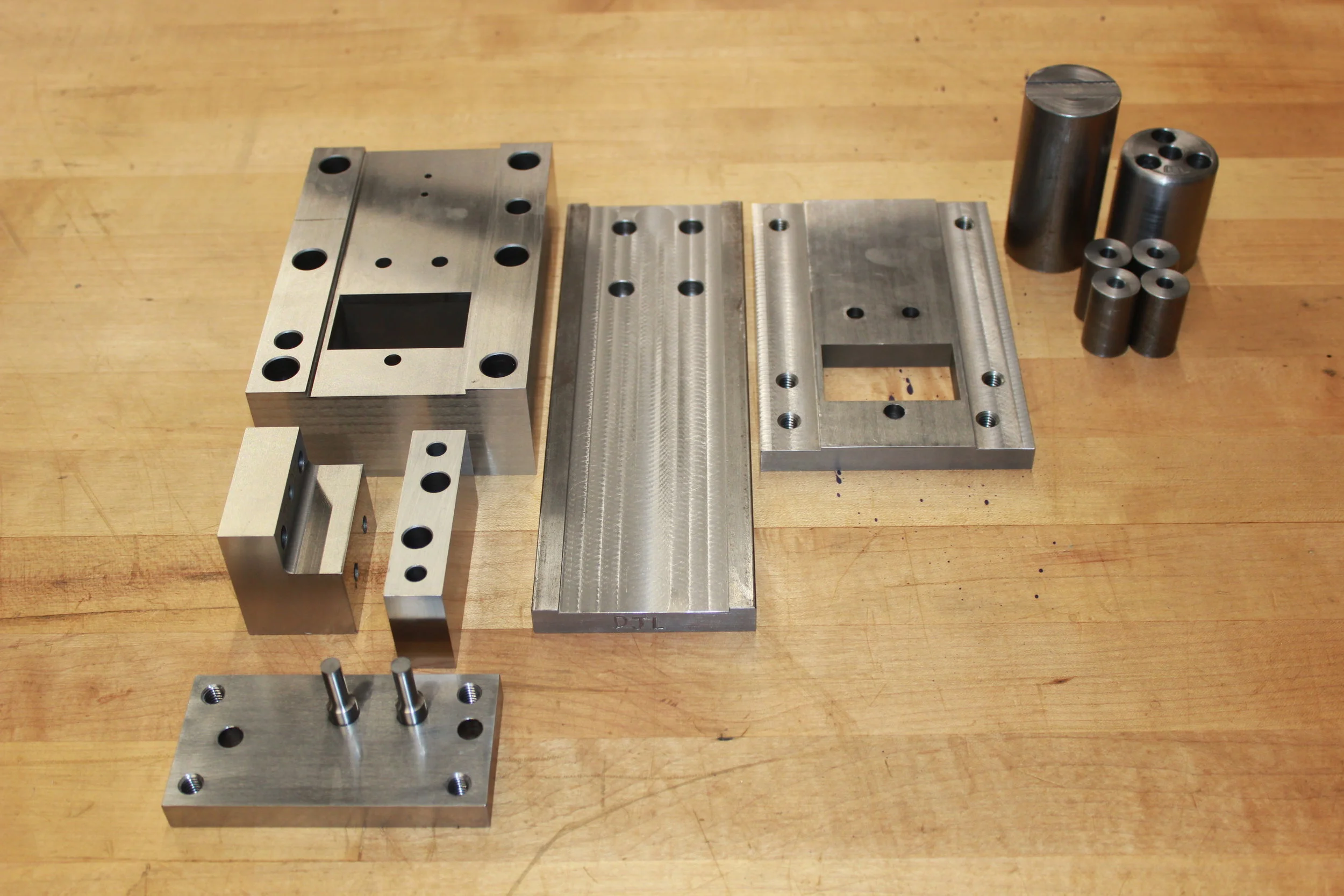

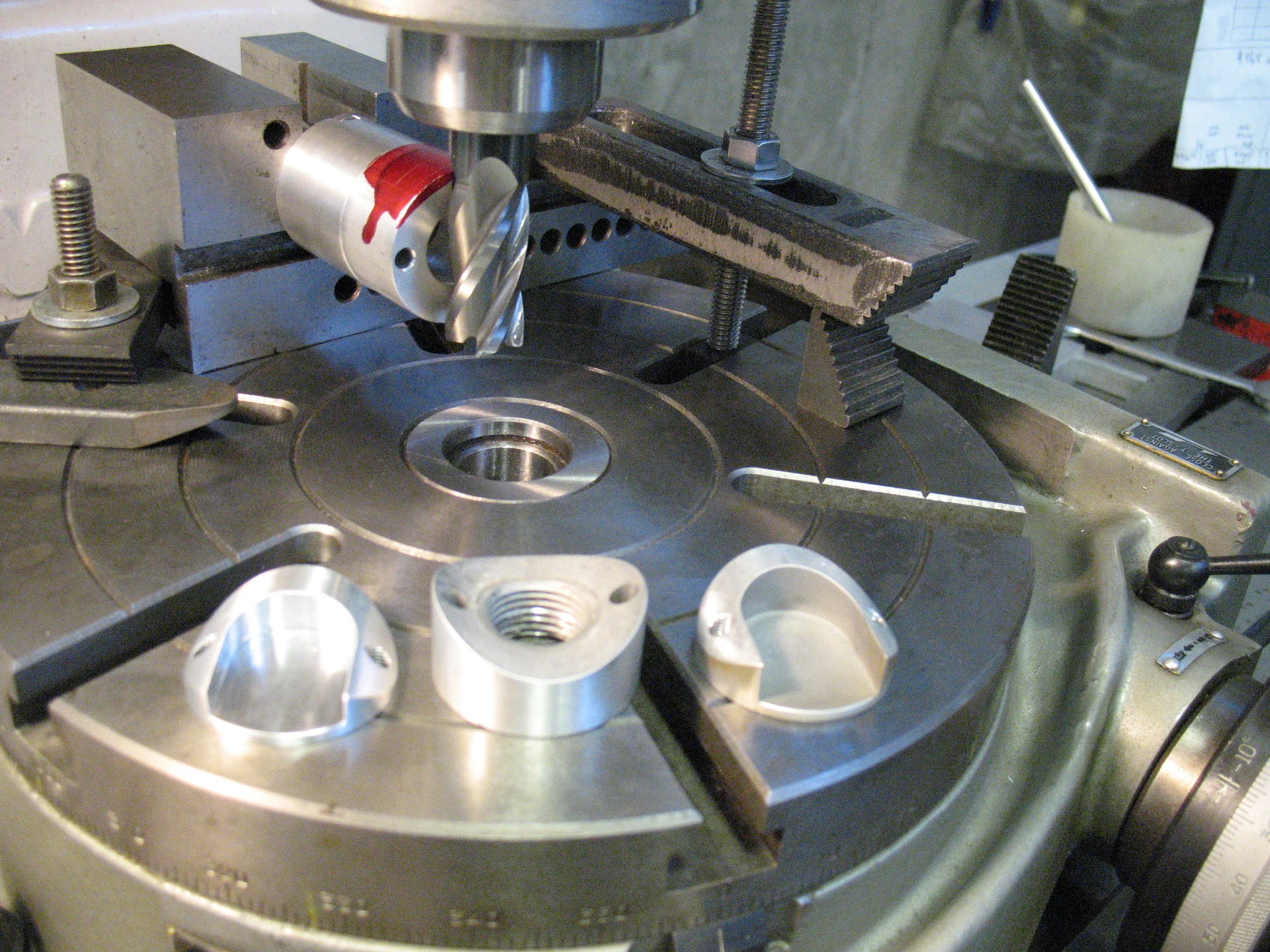

Tool & Die, Compound Washer Die

7

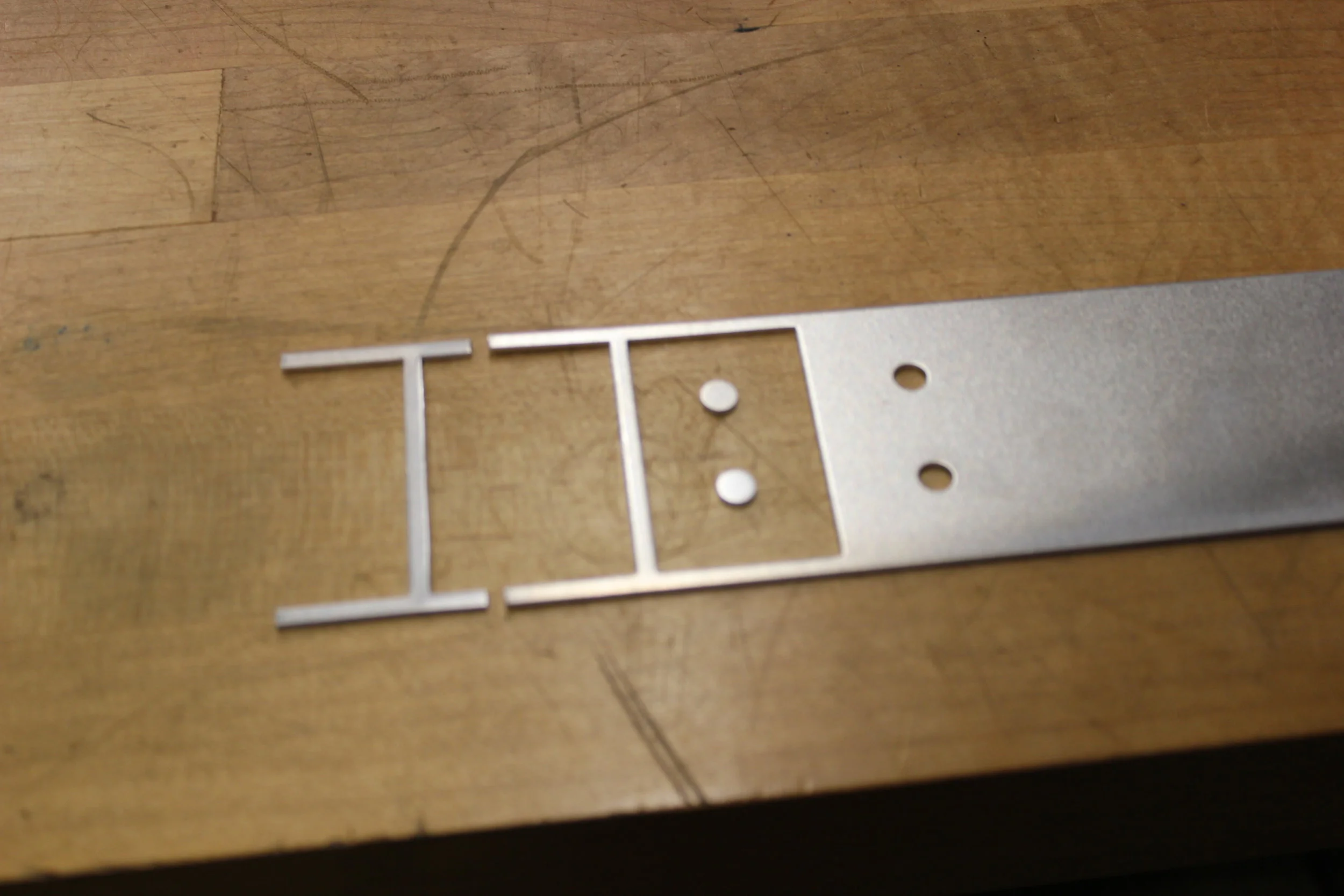

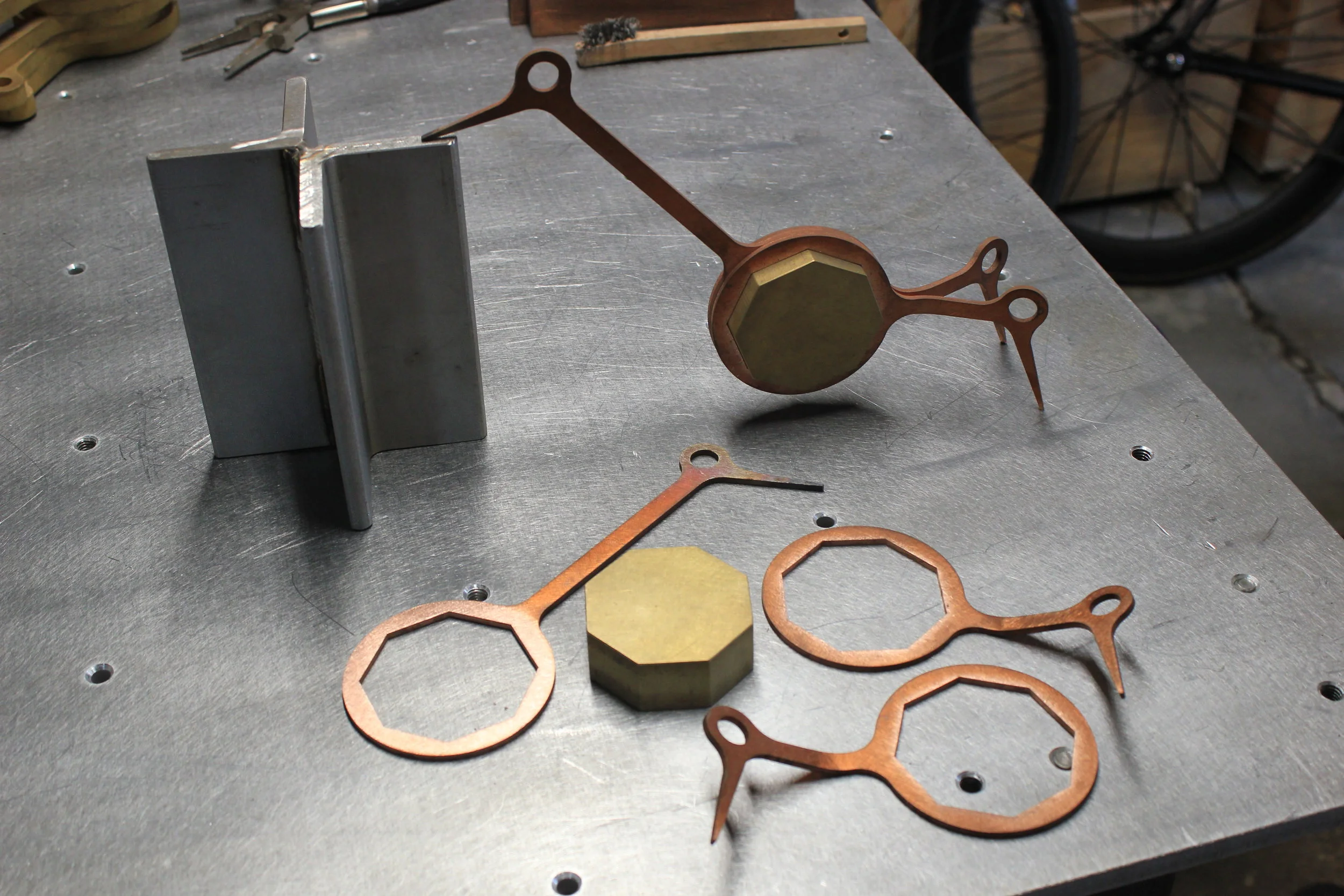

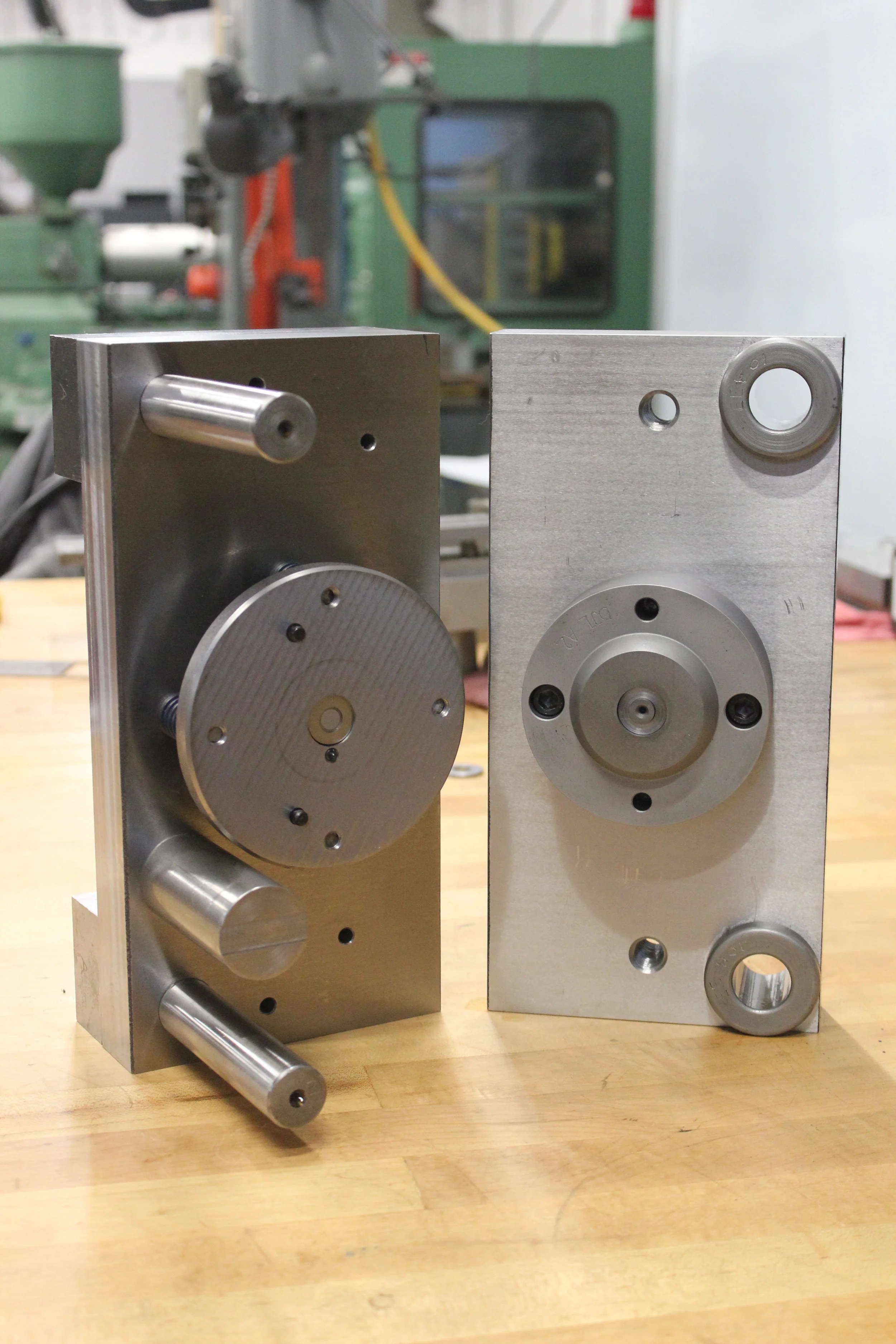

Tool & Die, Progressive Die, Magnetic Transfer Parallel Lamination's

6

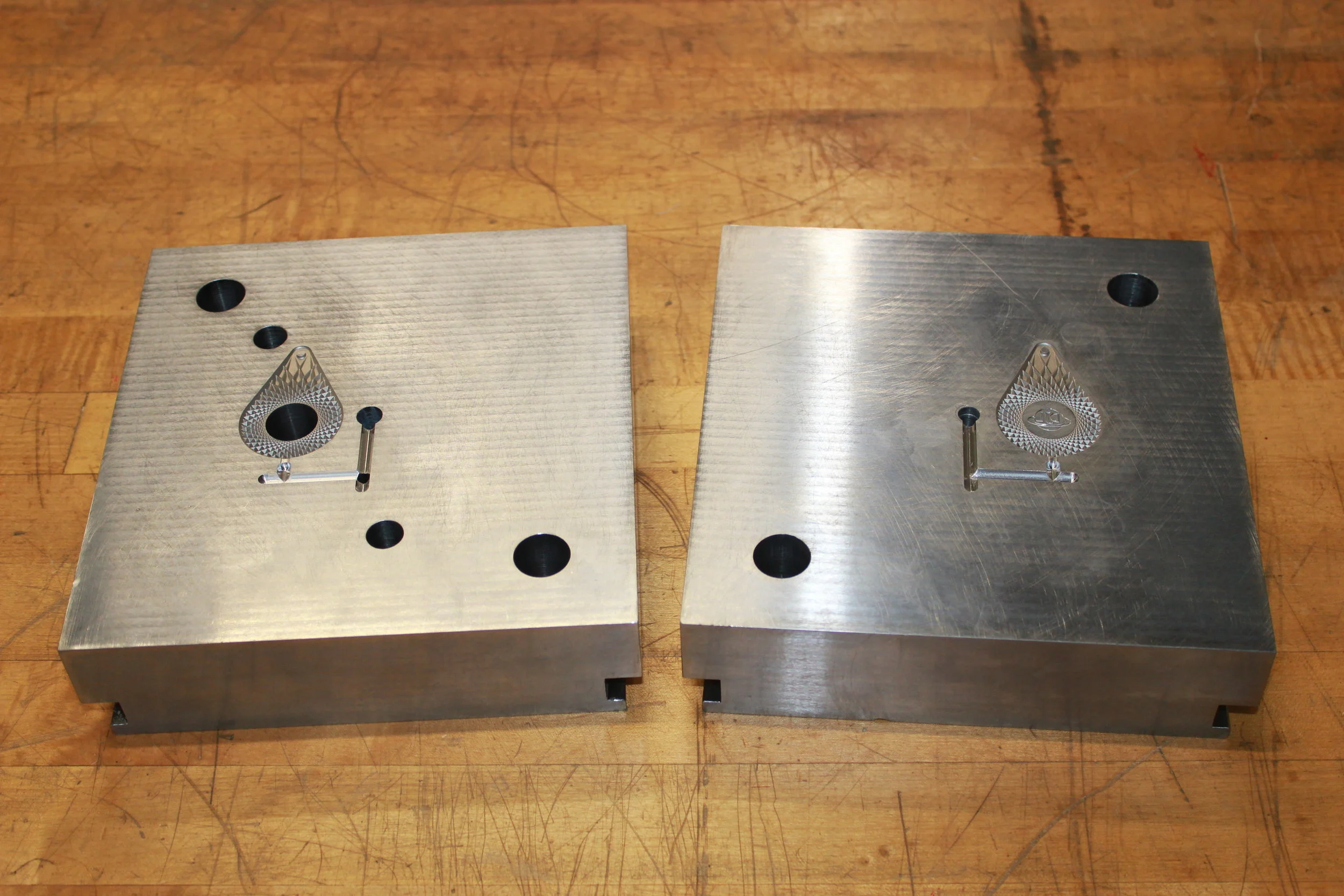

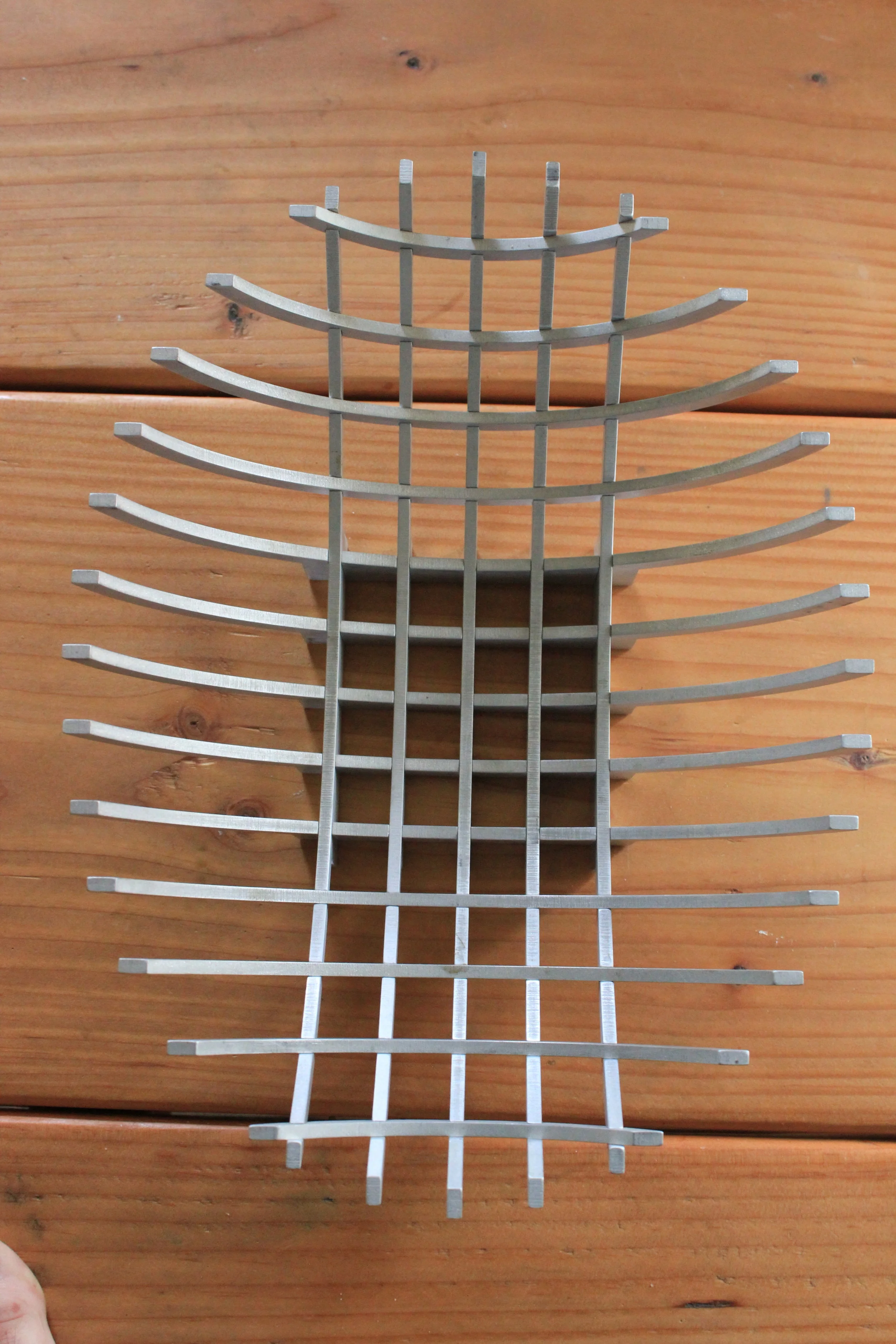

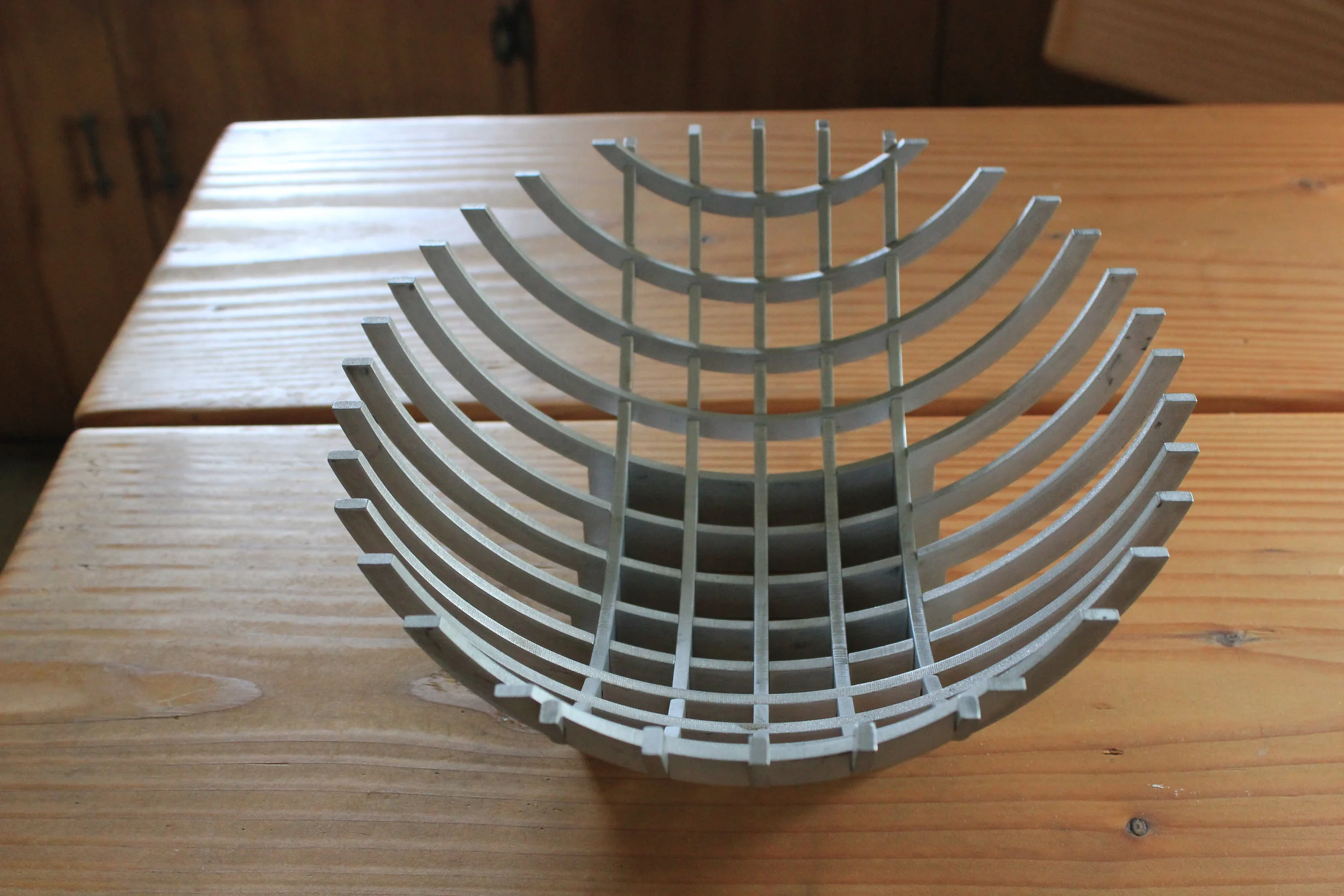

3D Modeling and Machining

6

Custom Seat Post Topper for Custom Bicycle

5

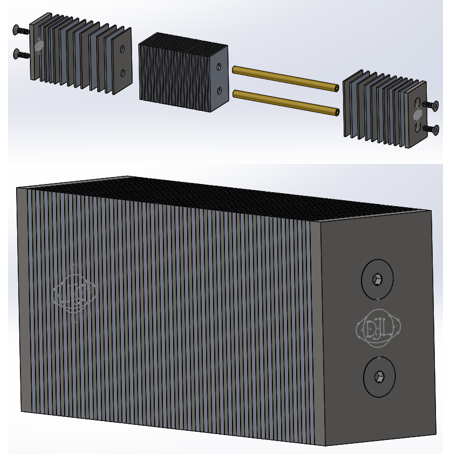

Blue Light Incubator

2

ABS Nuclear Eng Container

2

My Working Tool Box

1

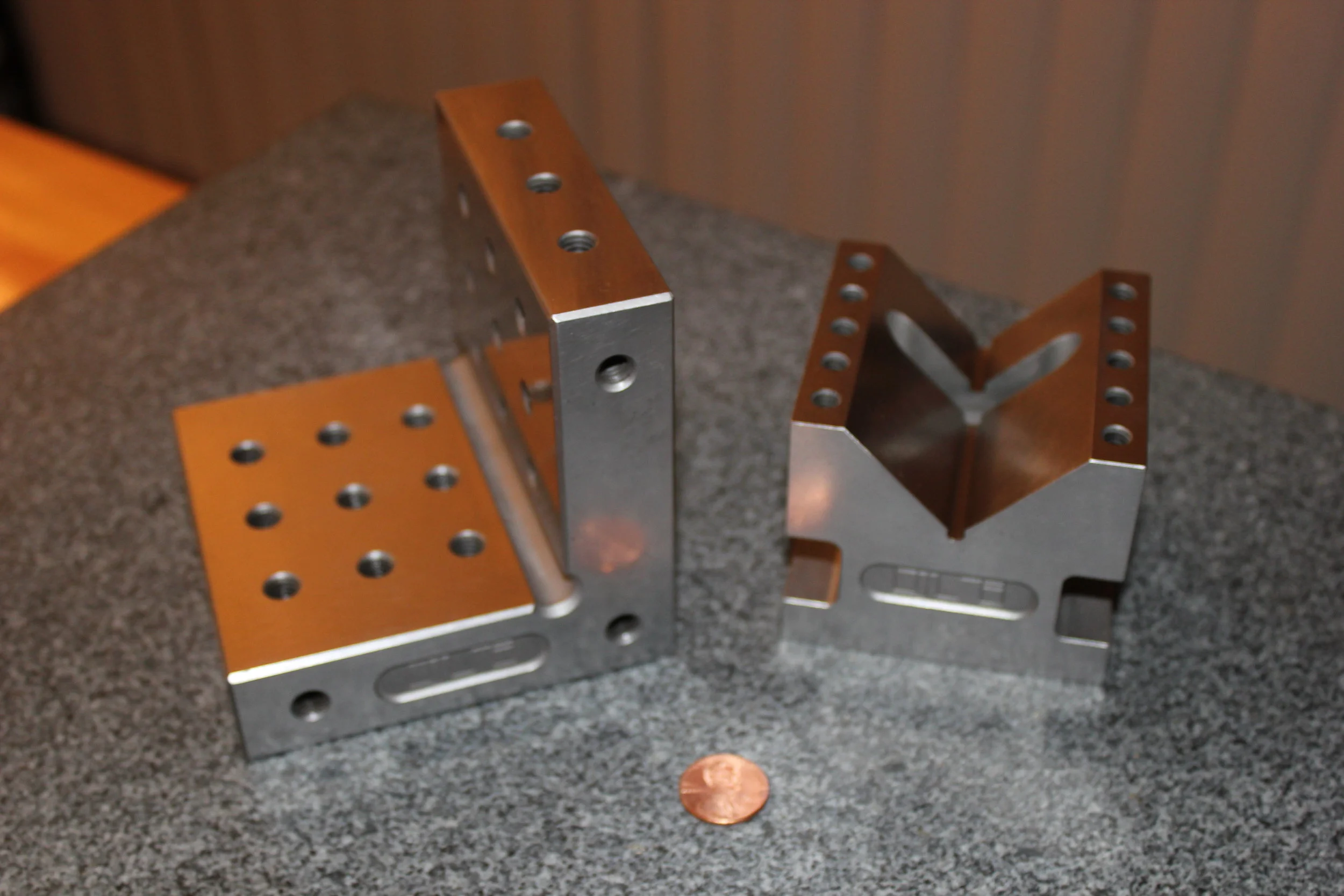

V-Block & Angle Plate

6

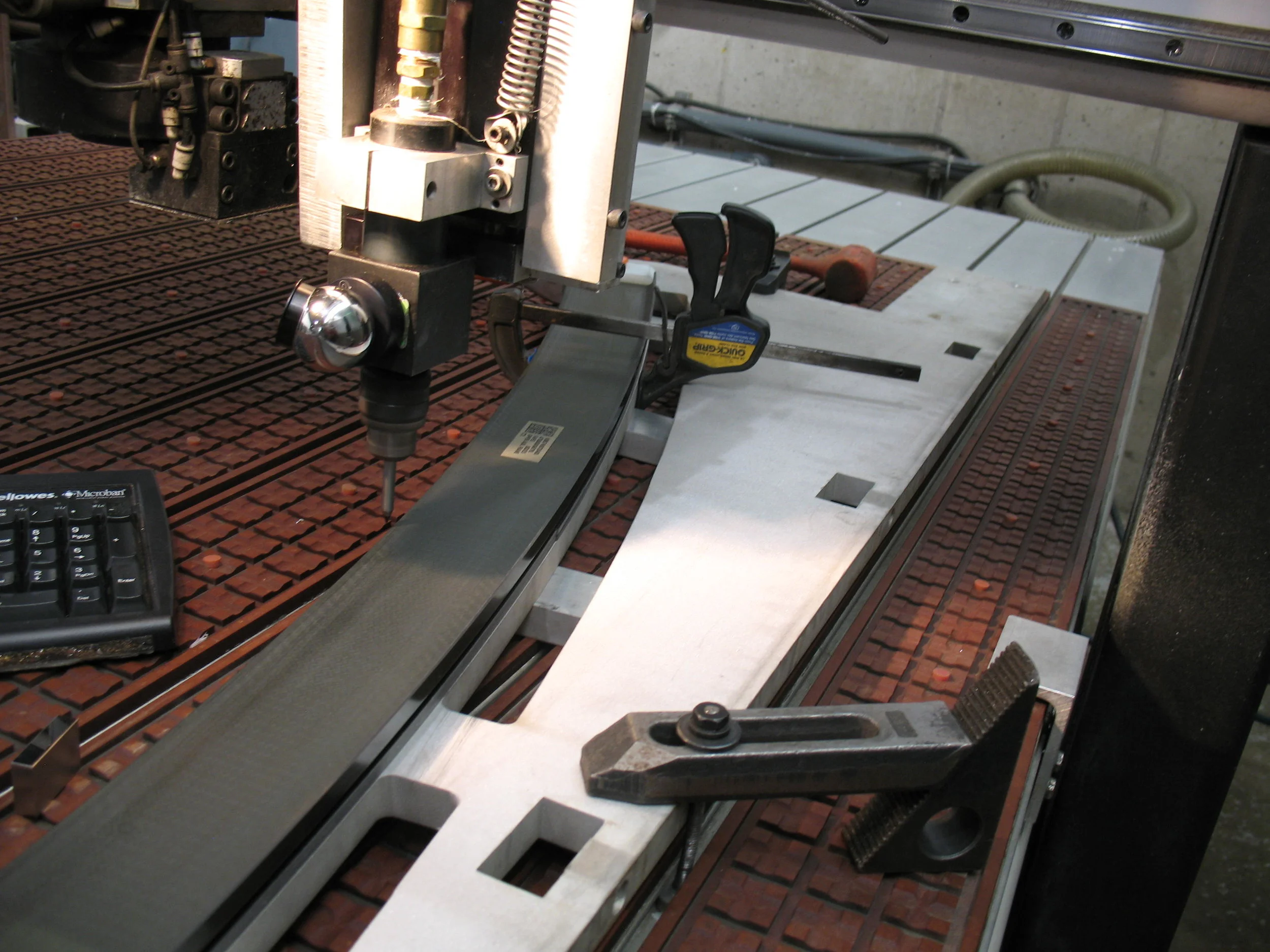

Water Jet Projects

4

Aerospace Projects

5

MANUAL LATHE

3

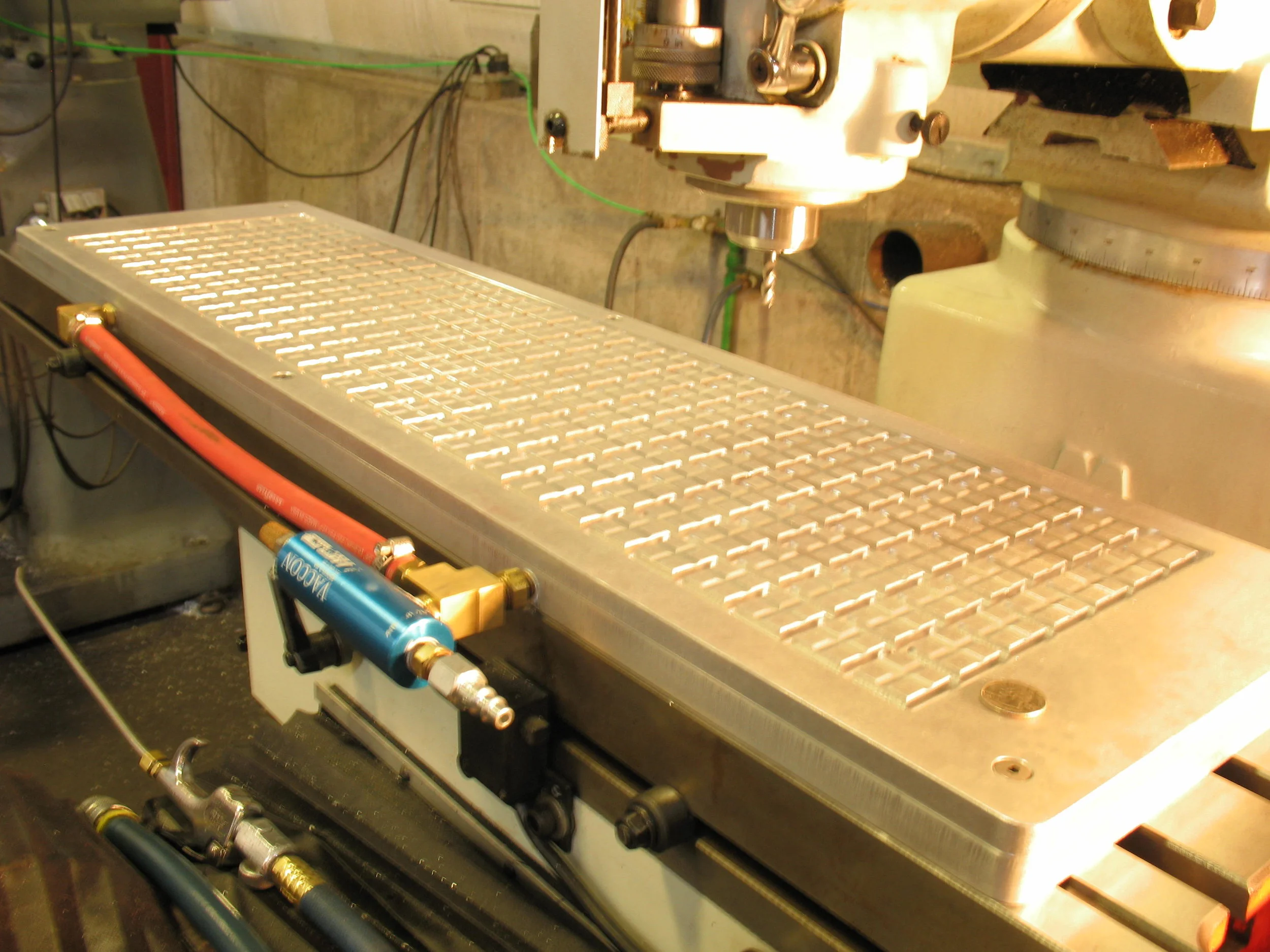

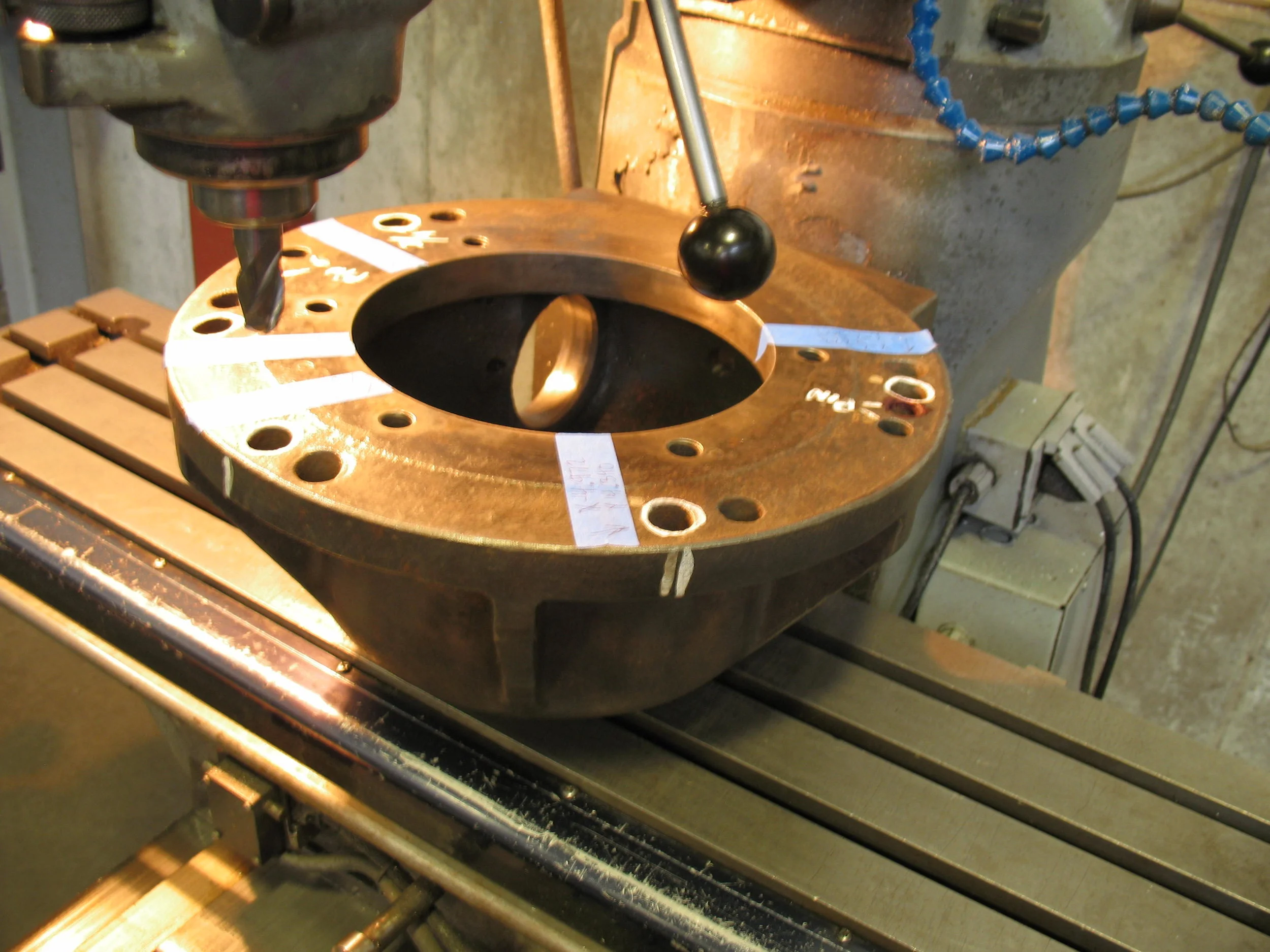

Vacuum Workholding

3

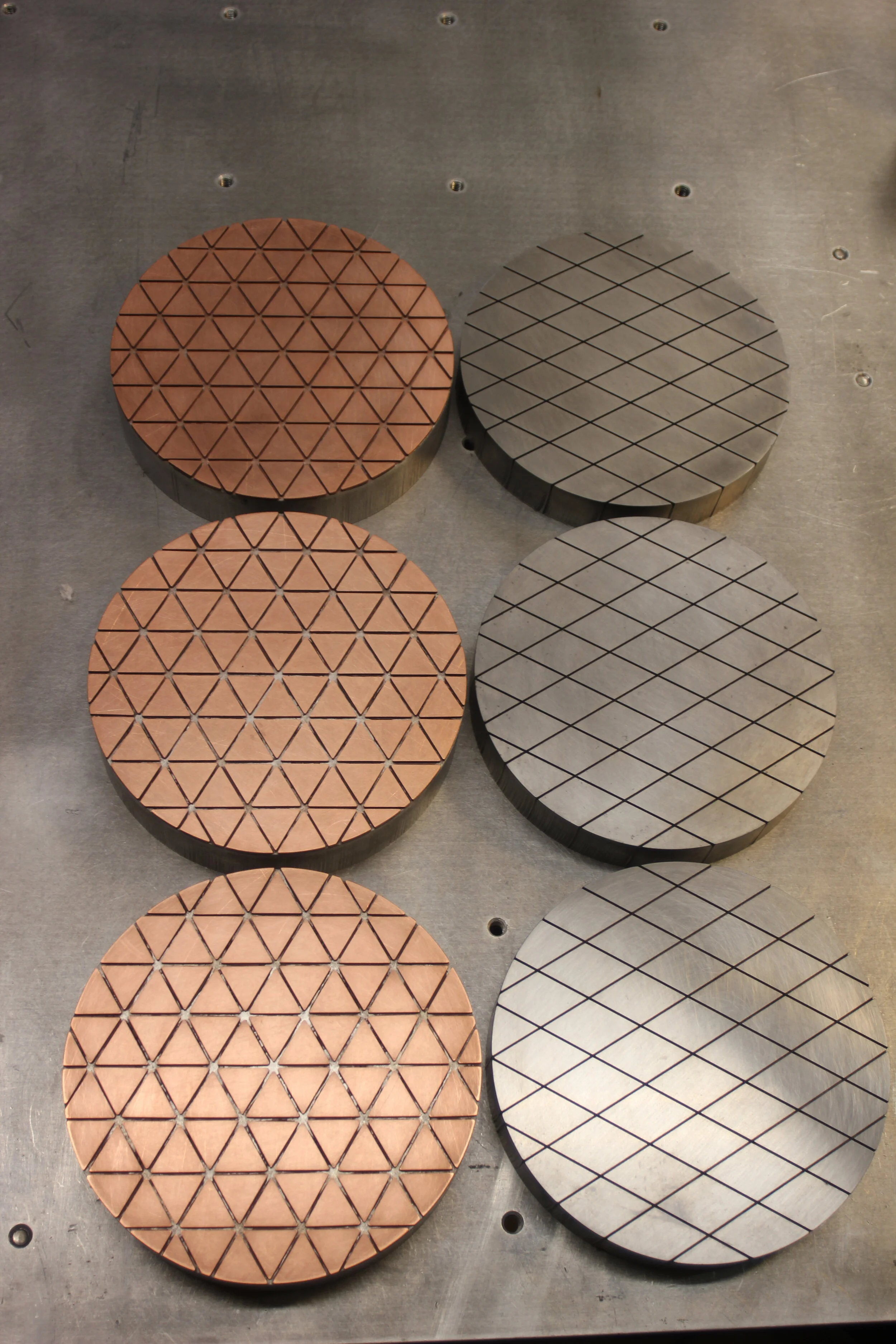

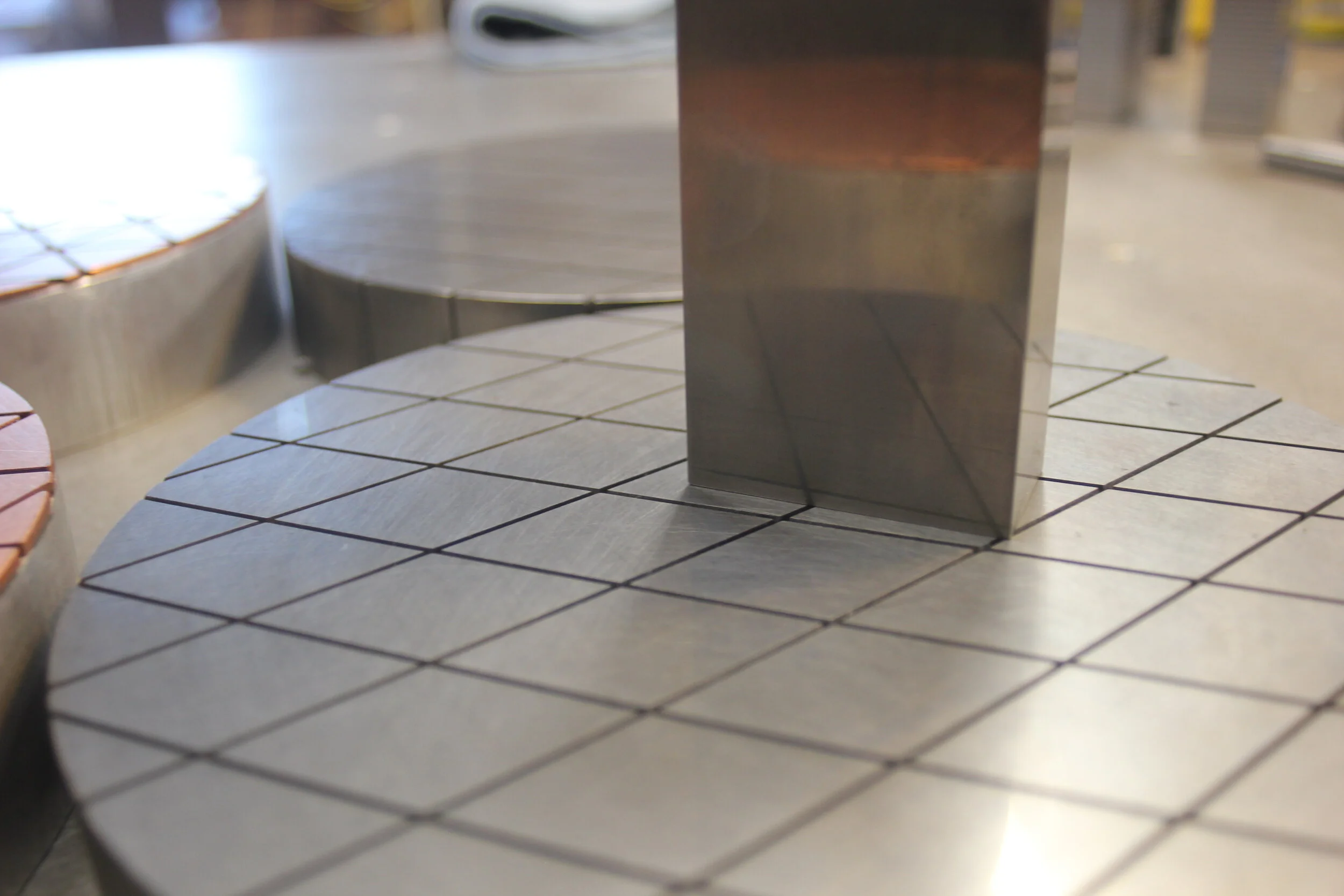

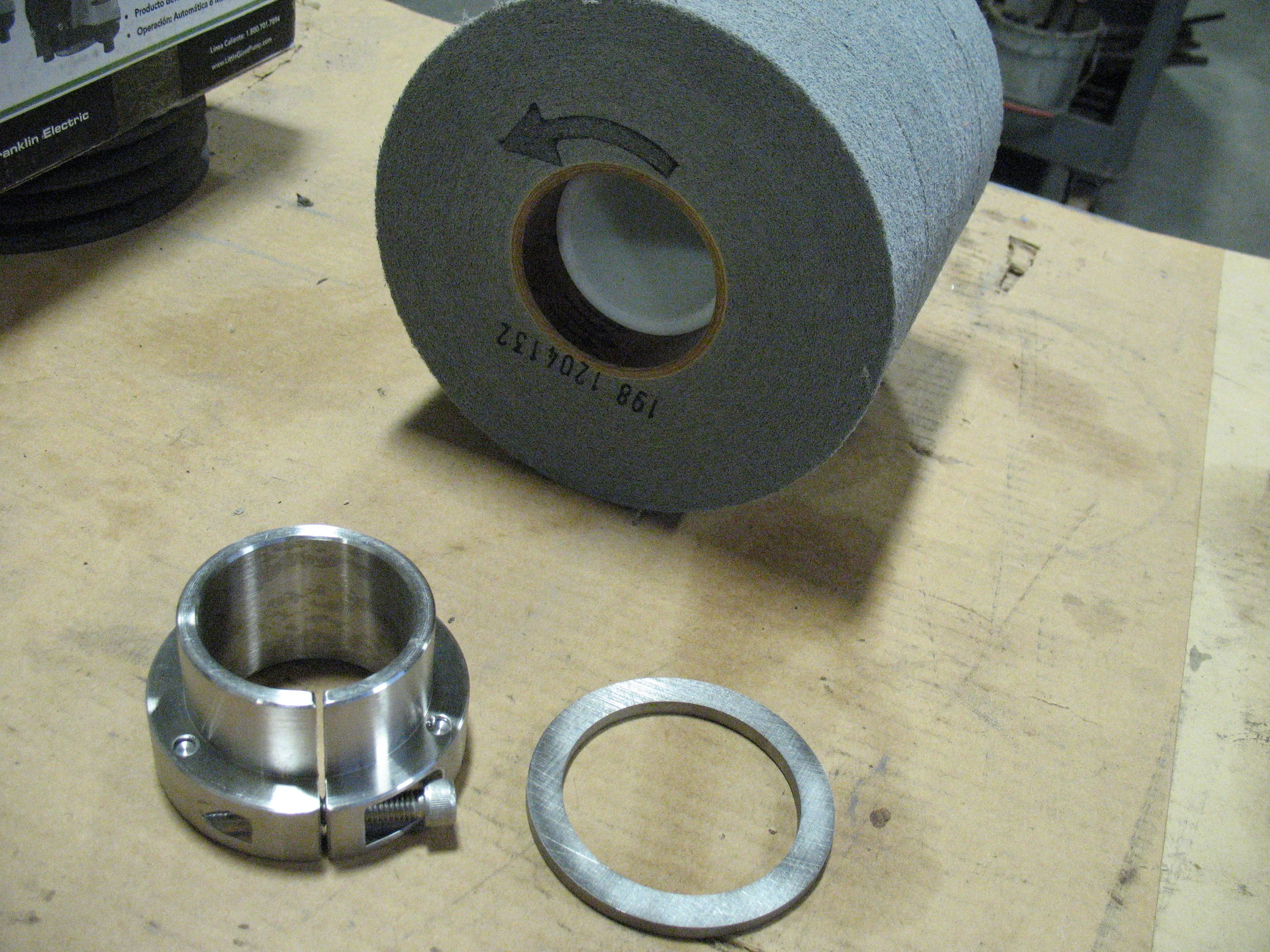

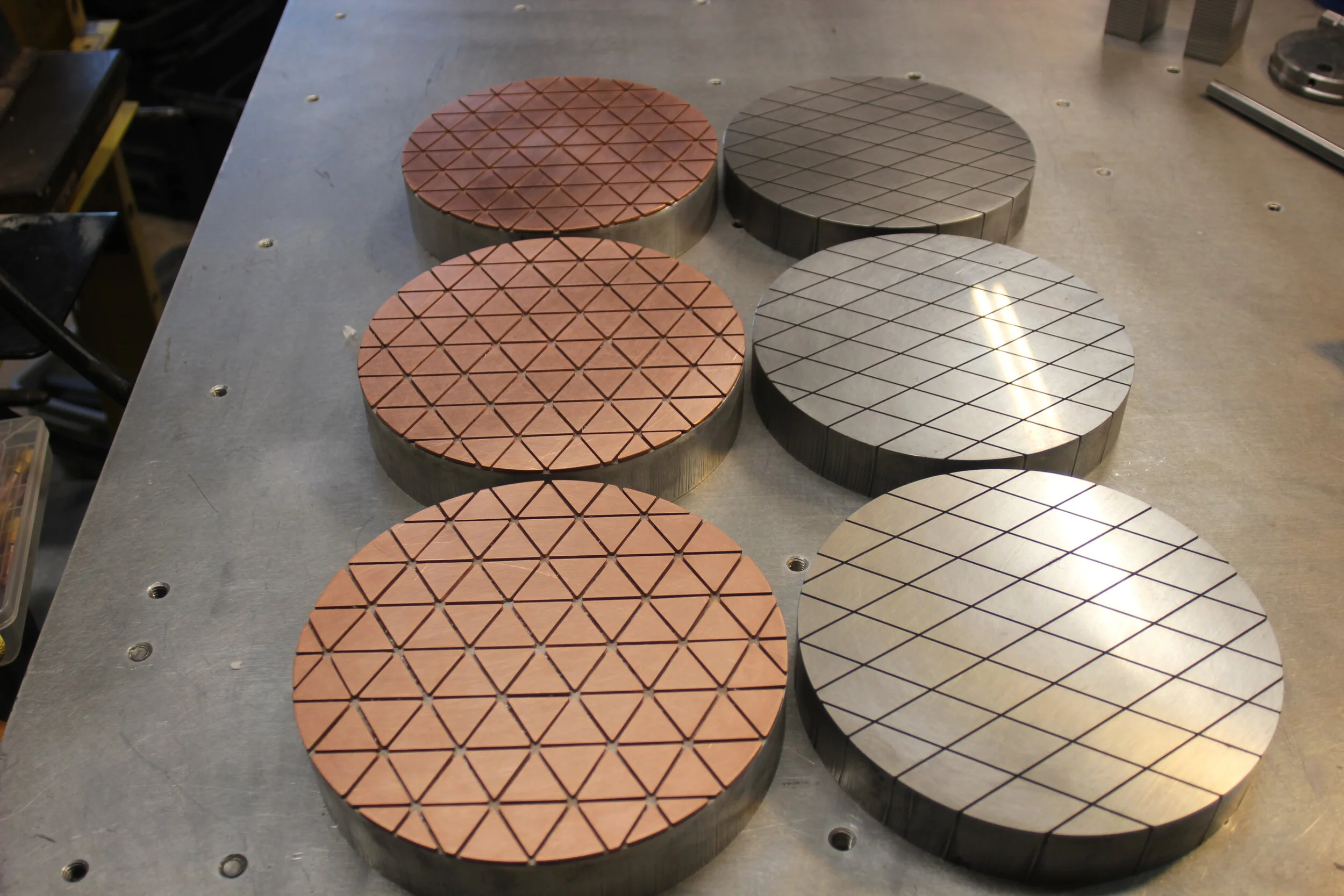

Lapping Plates

1

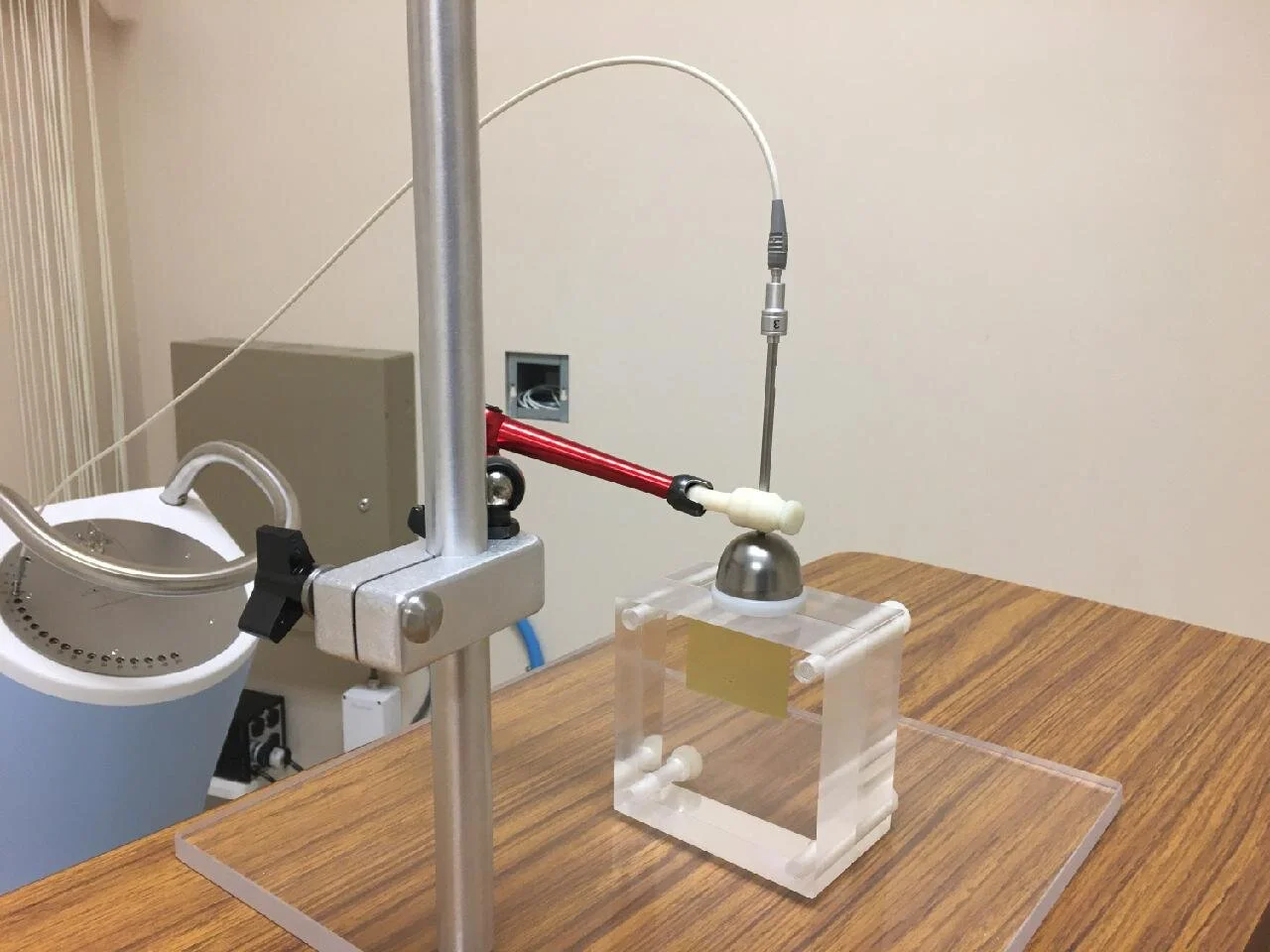

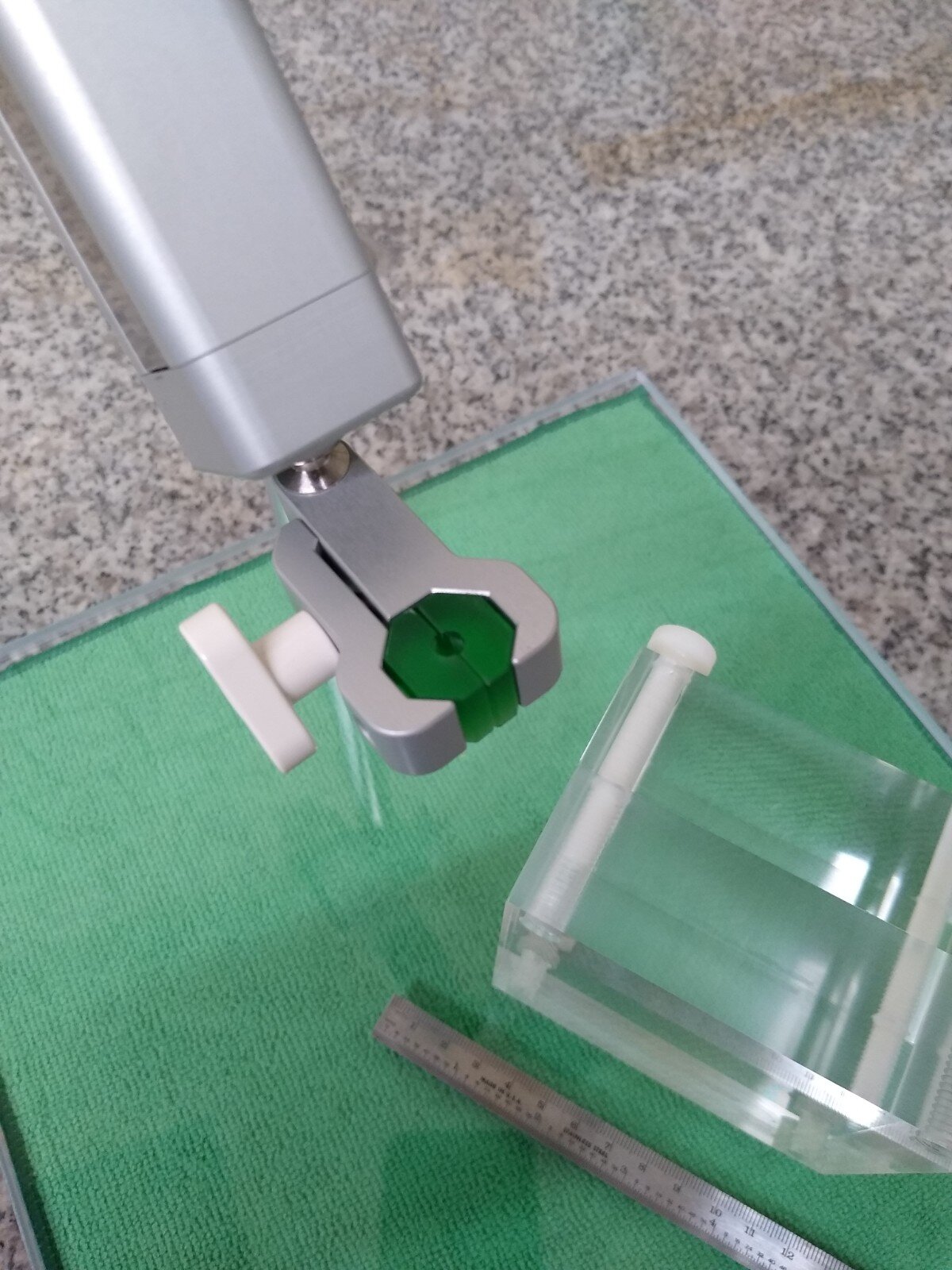

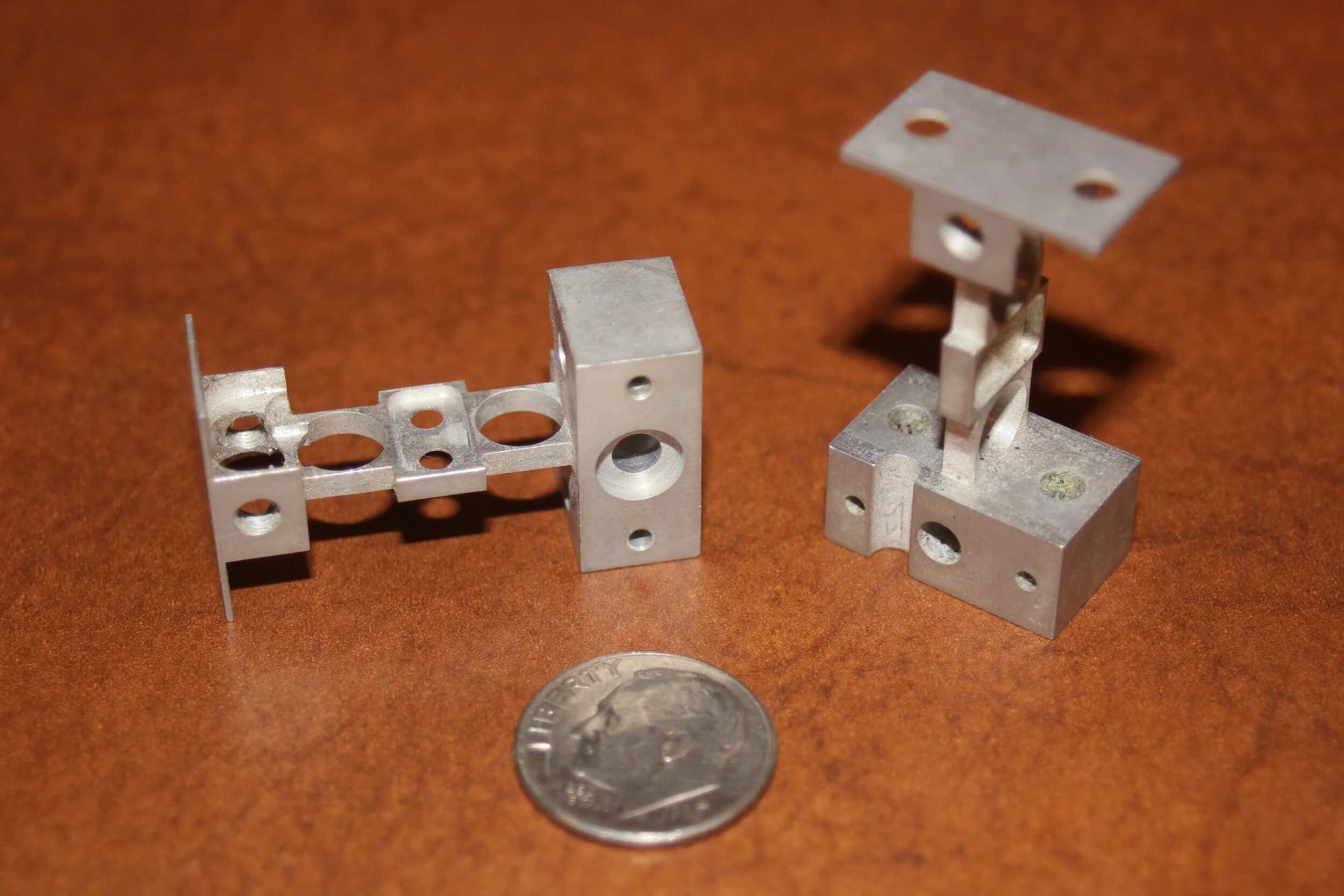

Load Sensor

5

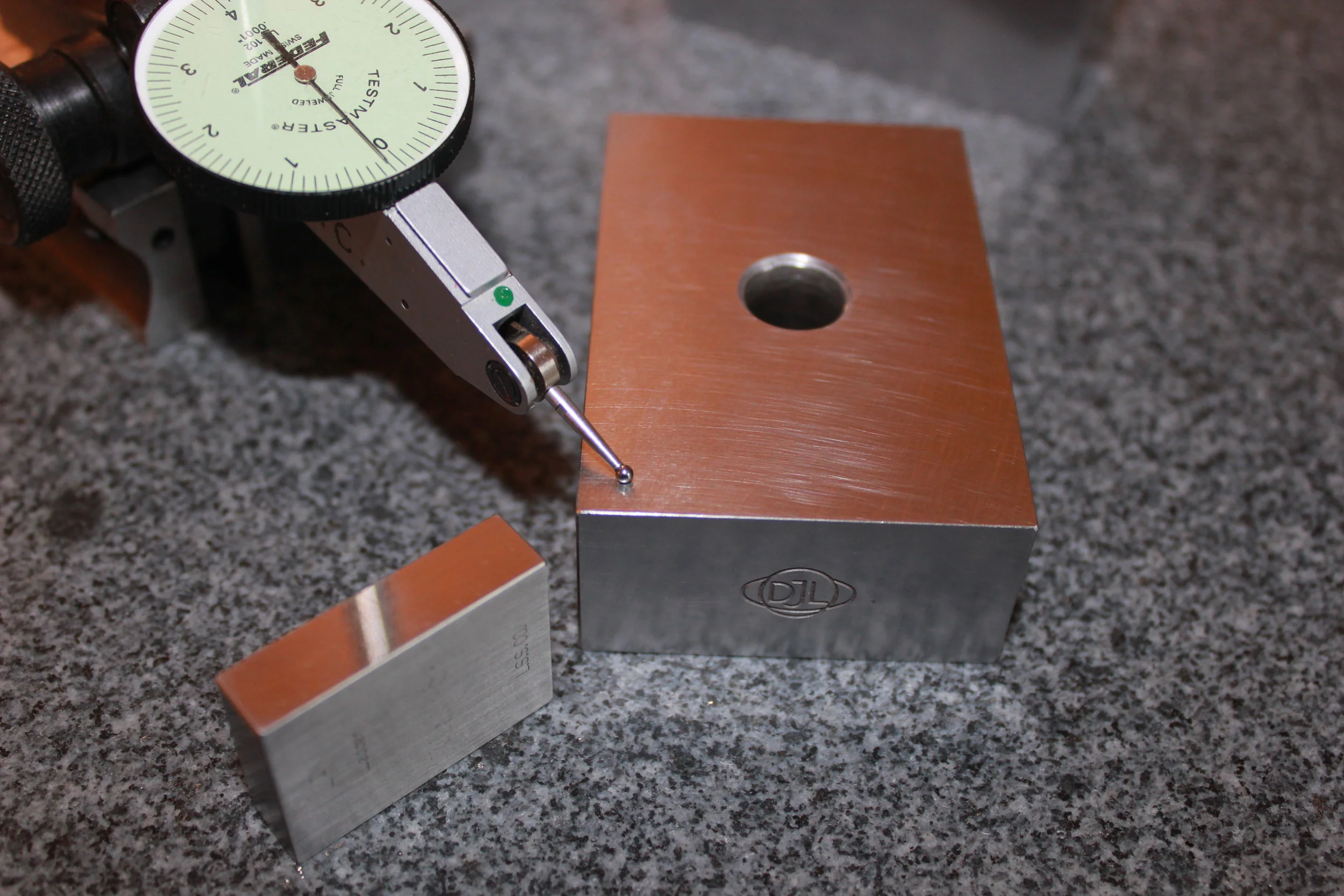

1x2x3 BLOCKS

2

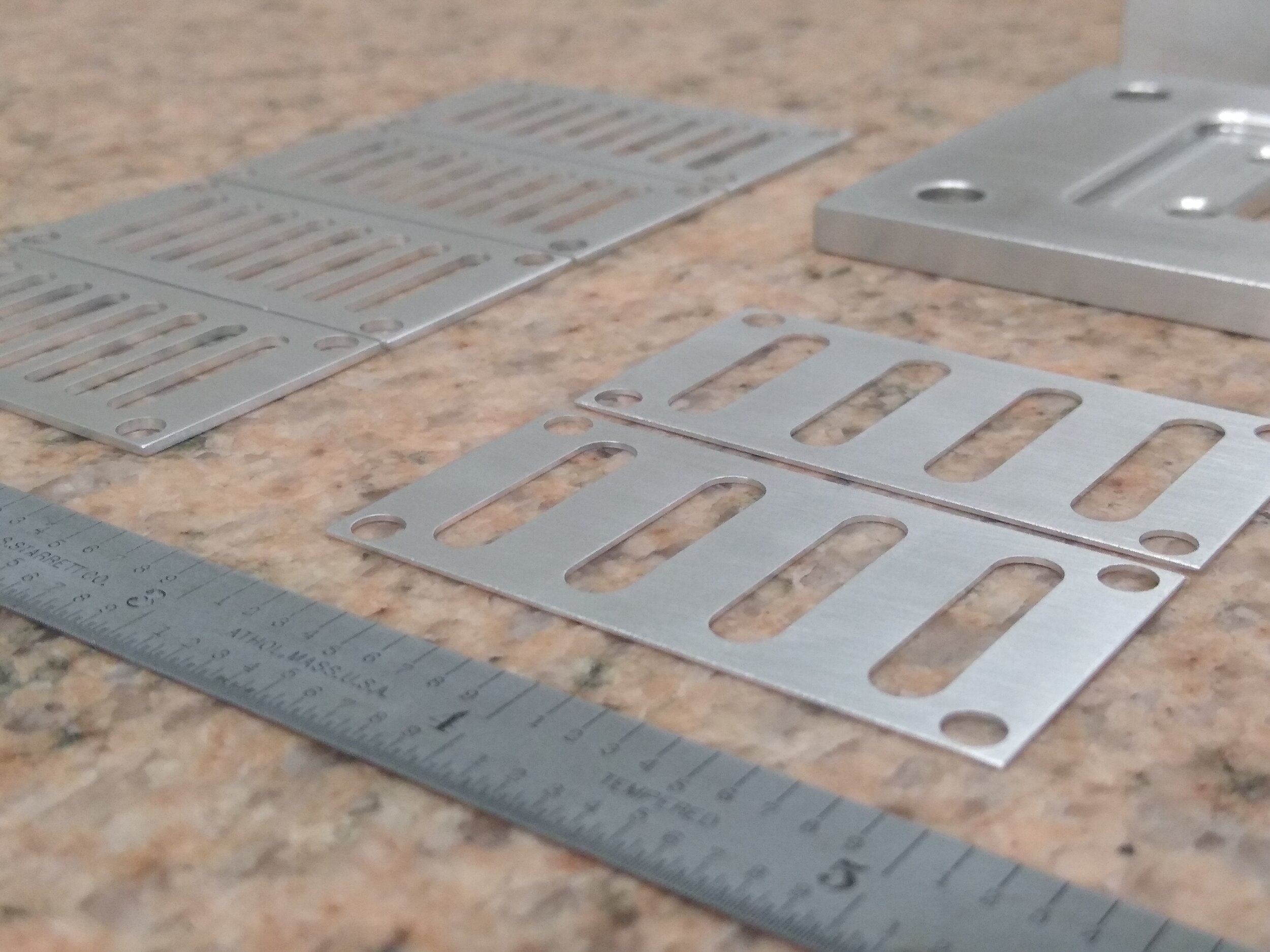

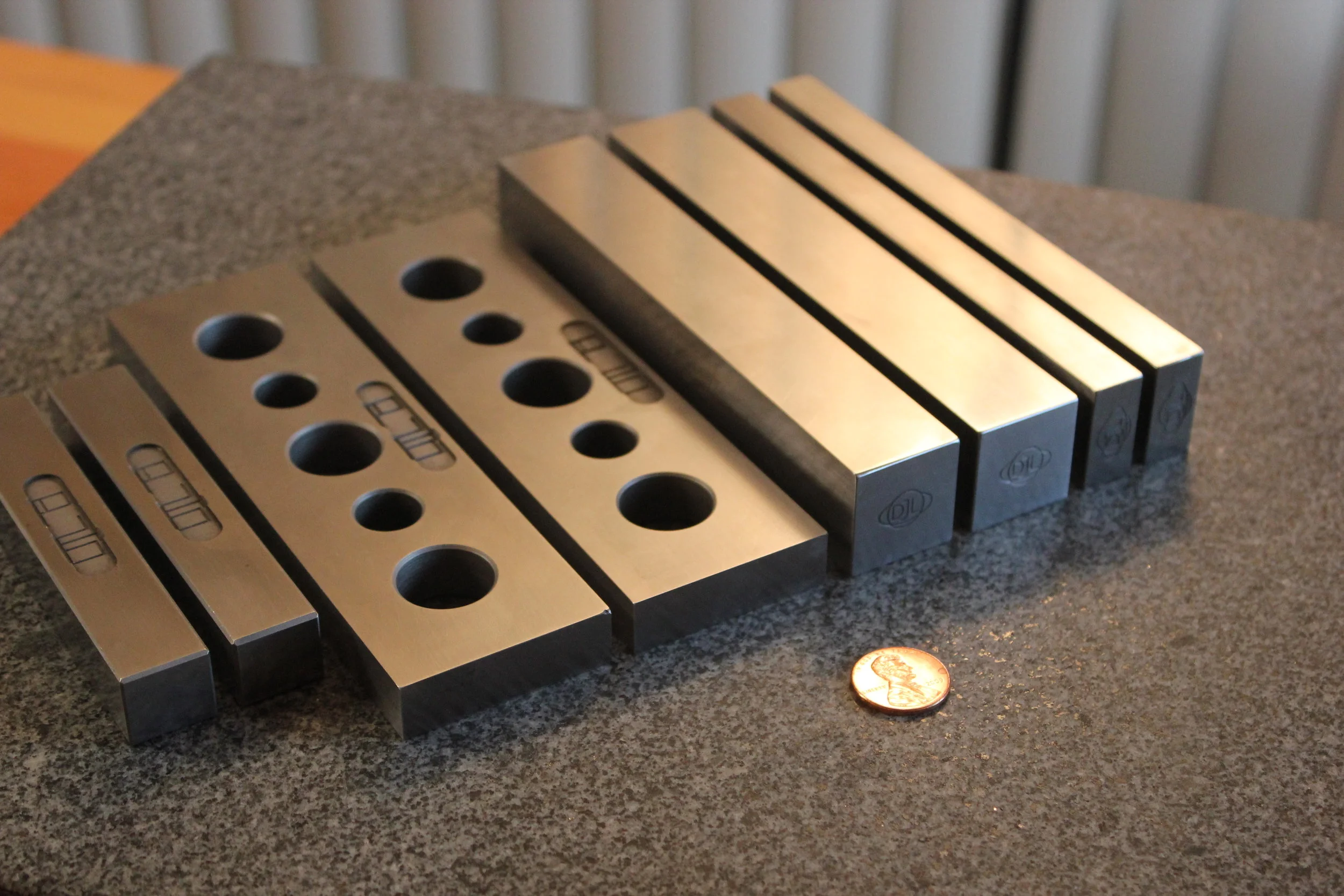

Parallel's

3

SQUARE COMPARATOR

1

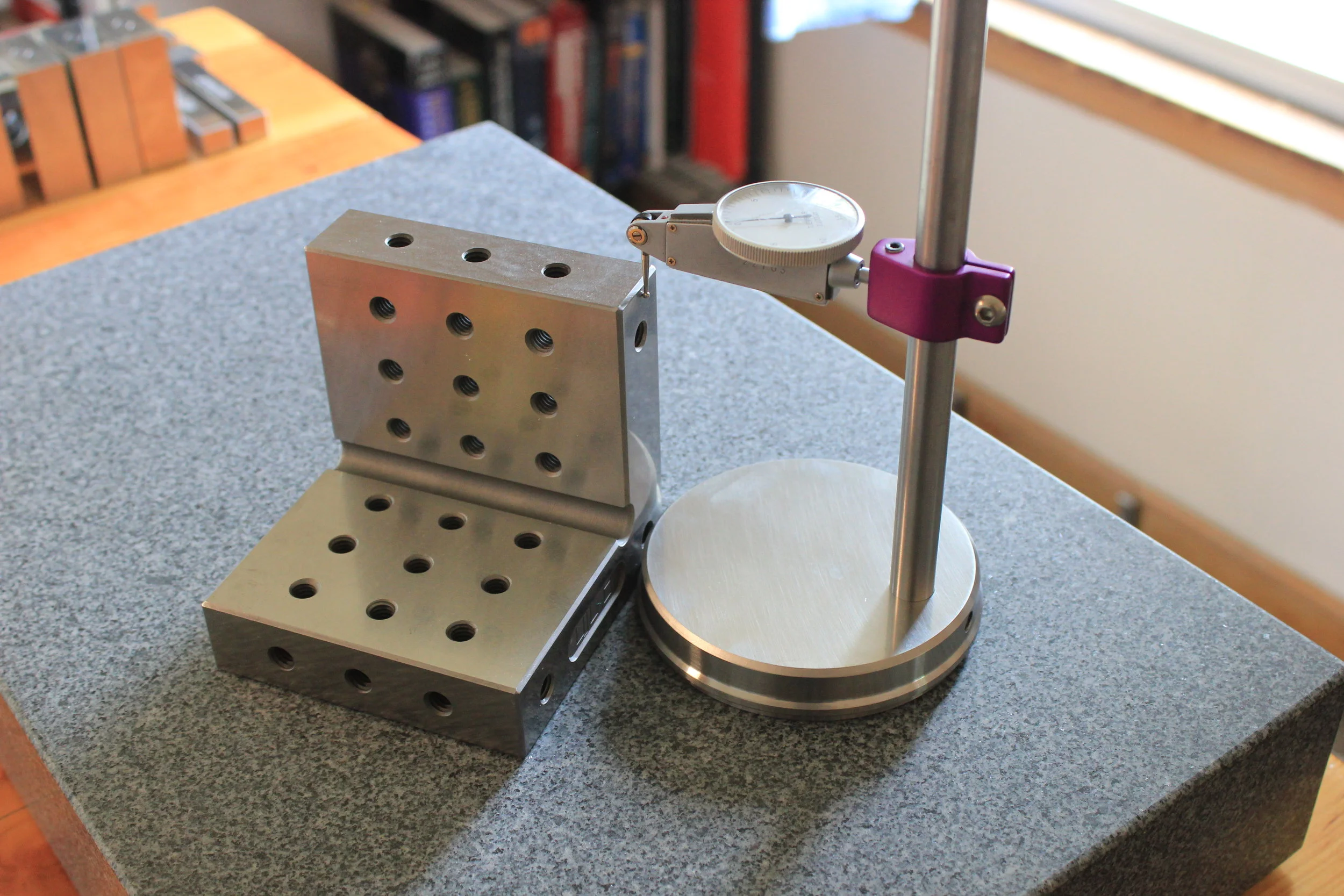

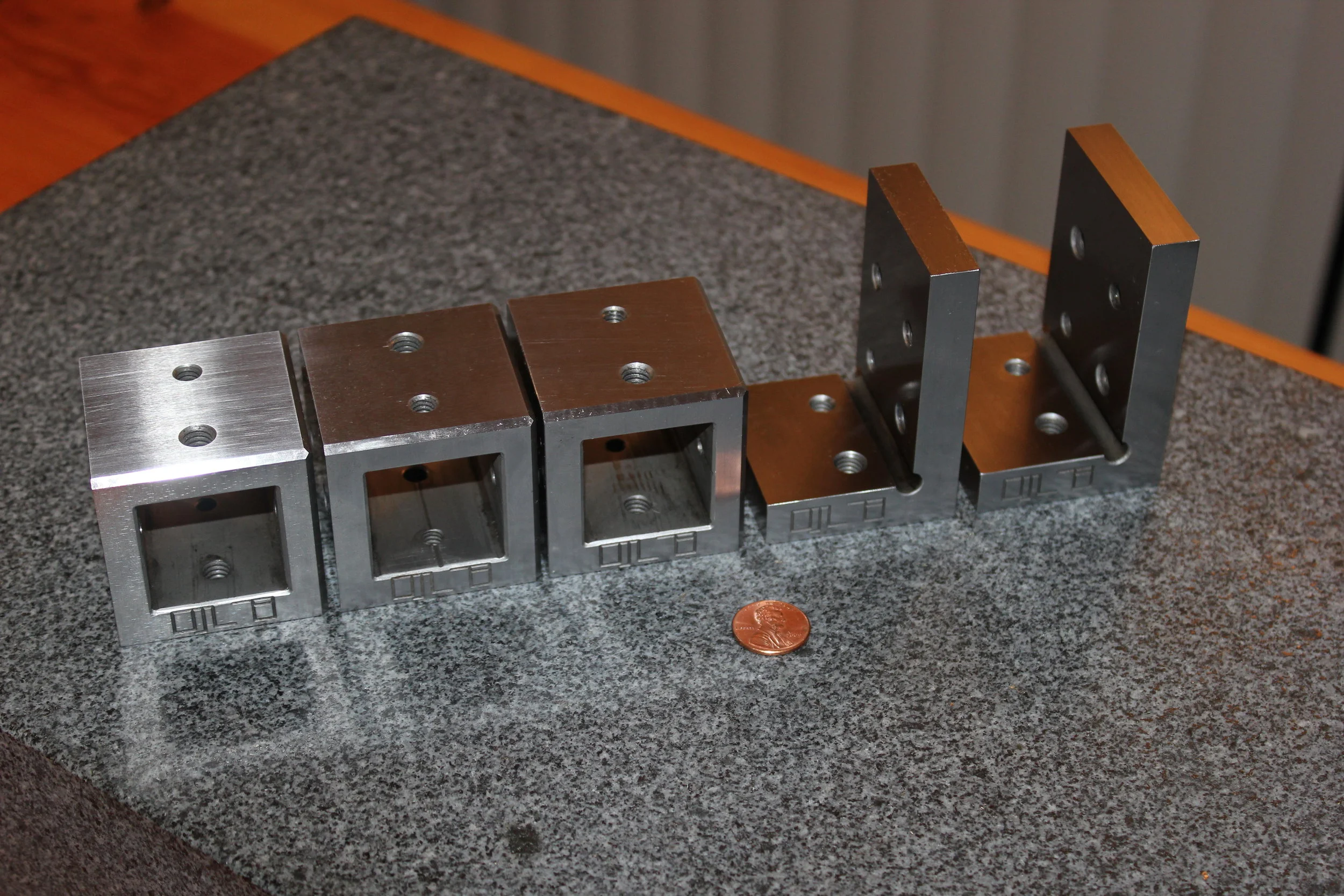

2x2 Cube & Angle Plate

4

Repair Parts

2

Custom Ophthalmic Lens Case

1

Welding Positioner

2

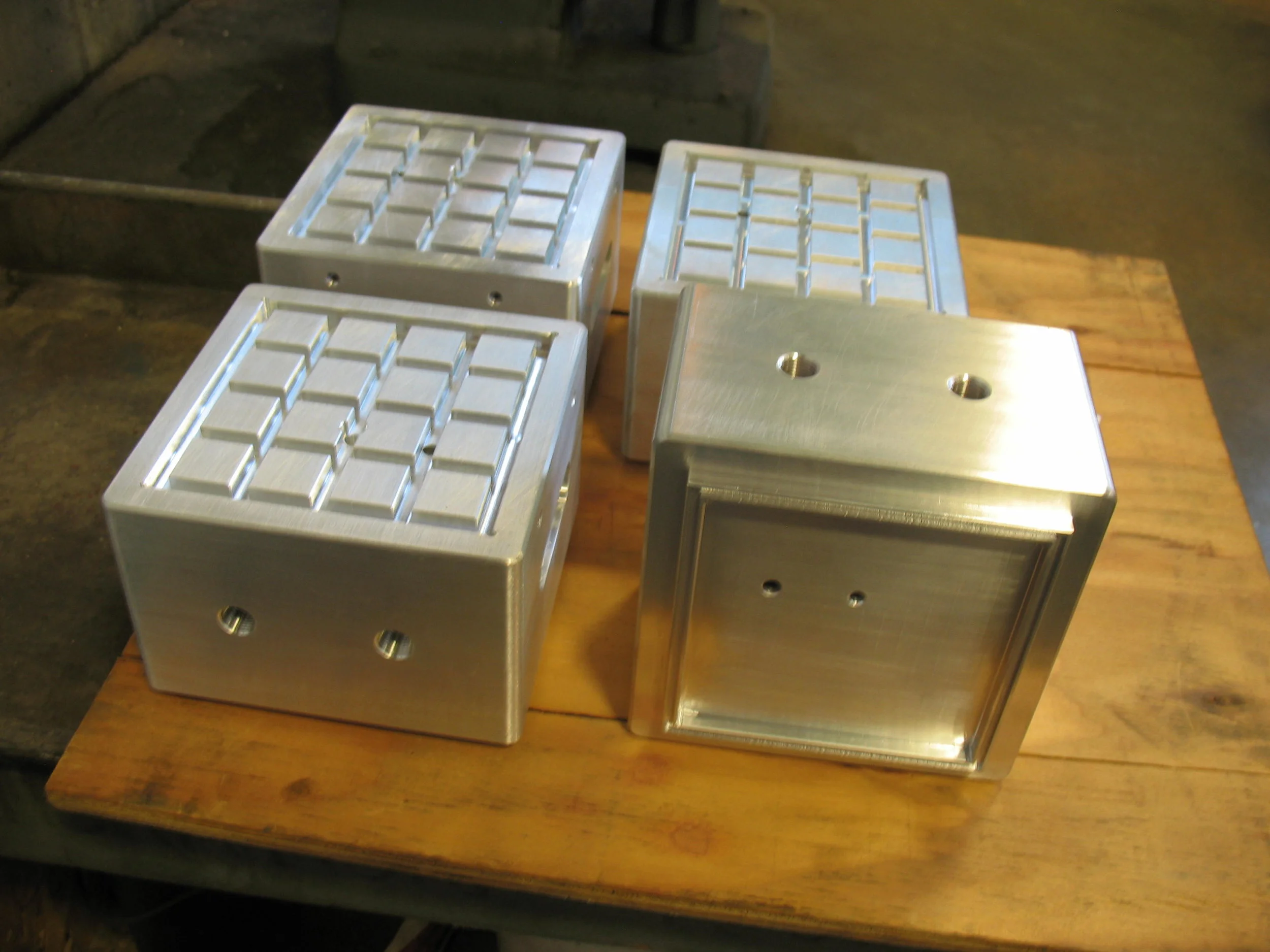

Chemistry Heating Blocks

2

Test