8

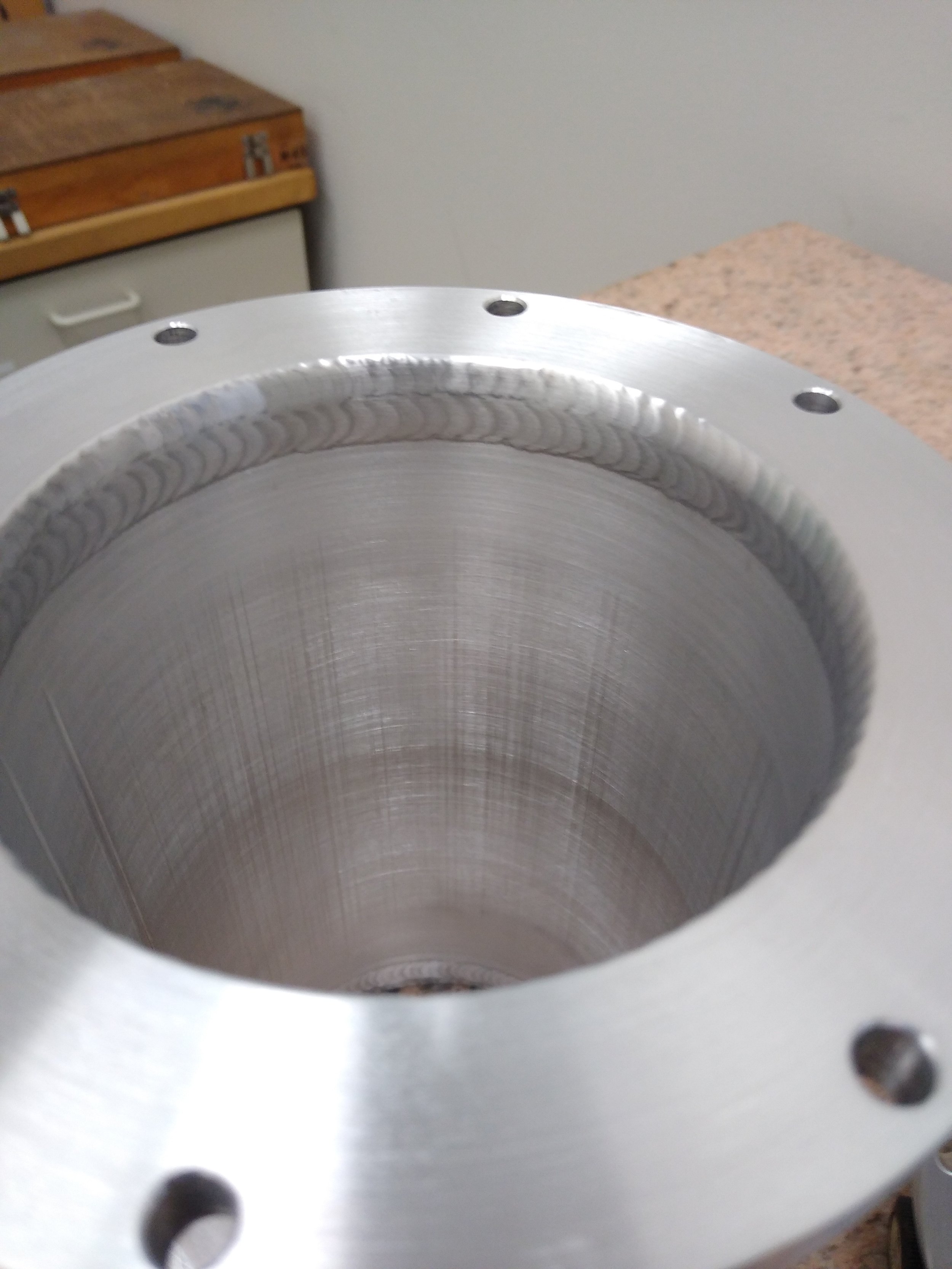

Vacuum Chambers

18

Large Vacuum Device for Ion Spectroscopy

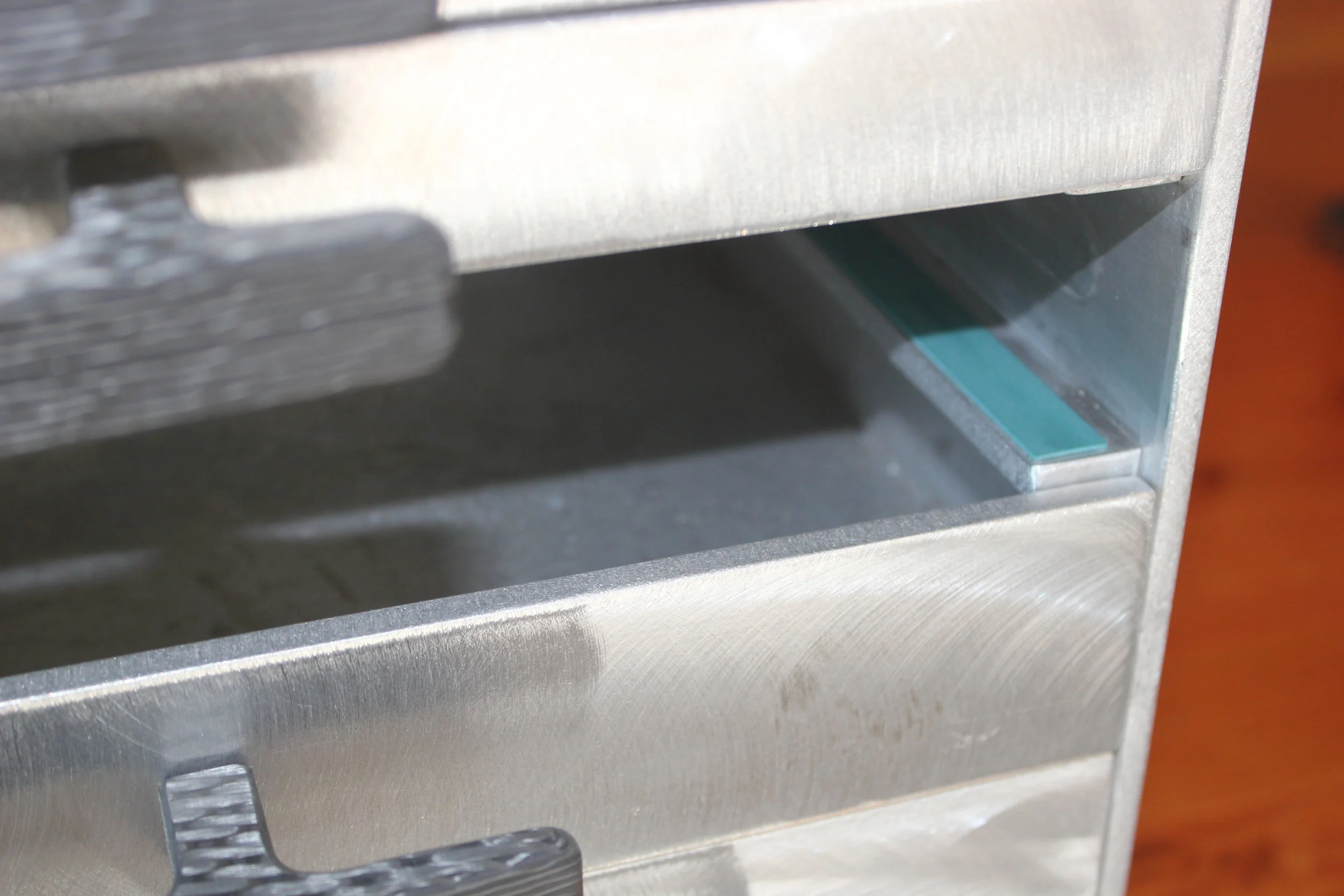

6

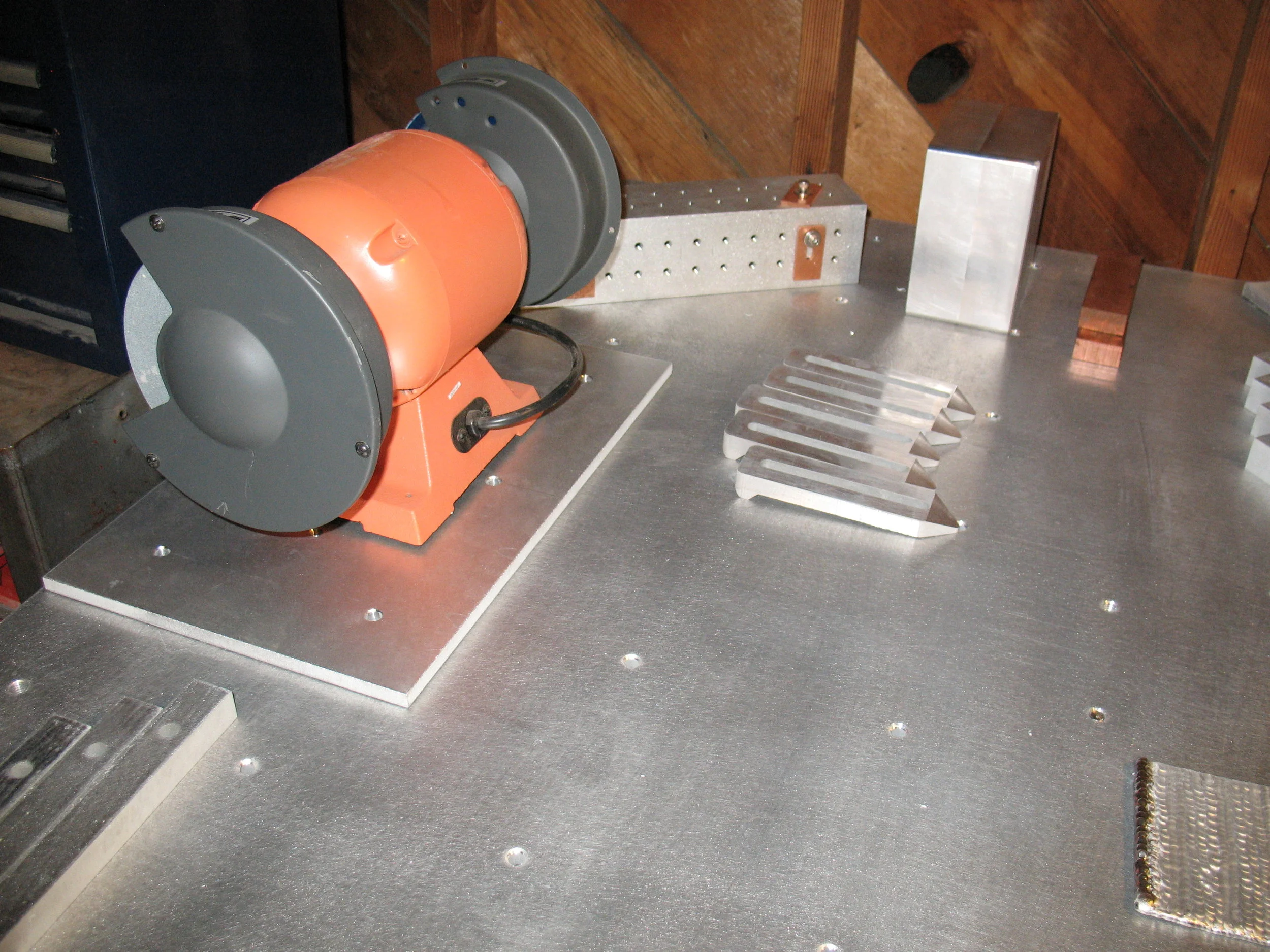

Custom Laser Breadboard Table

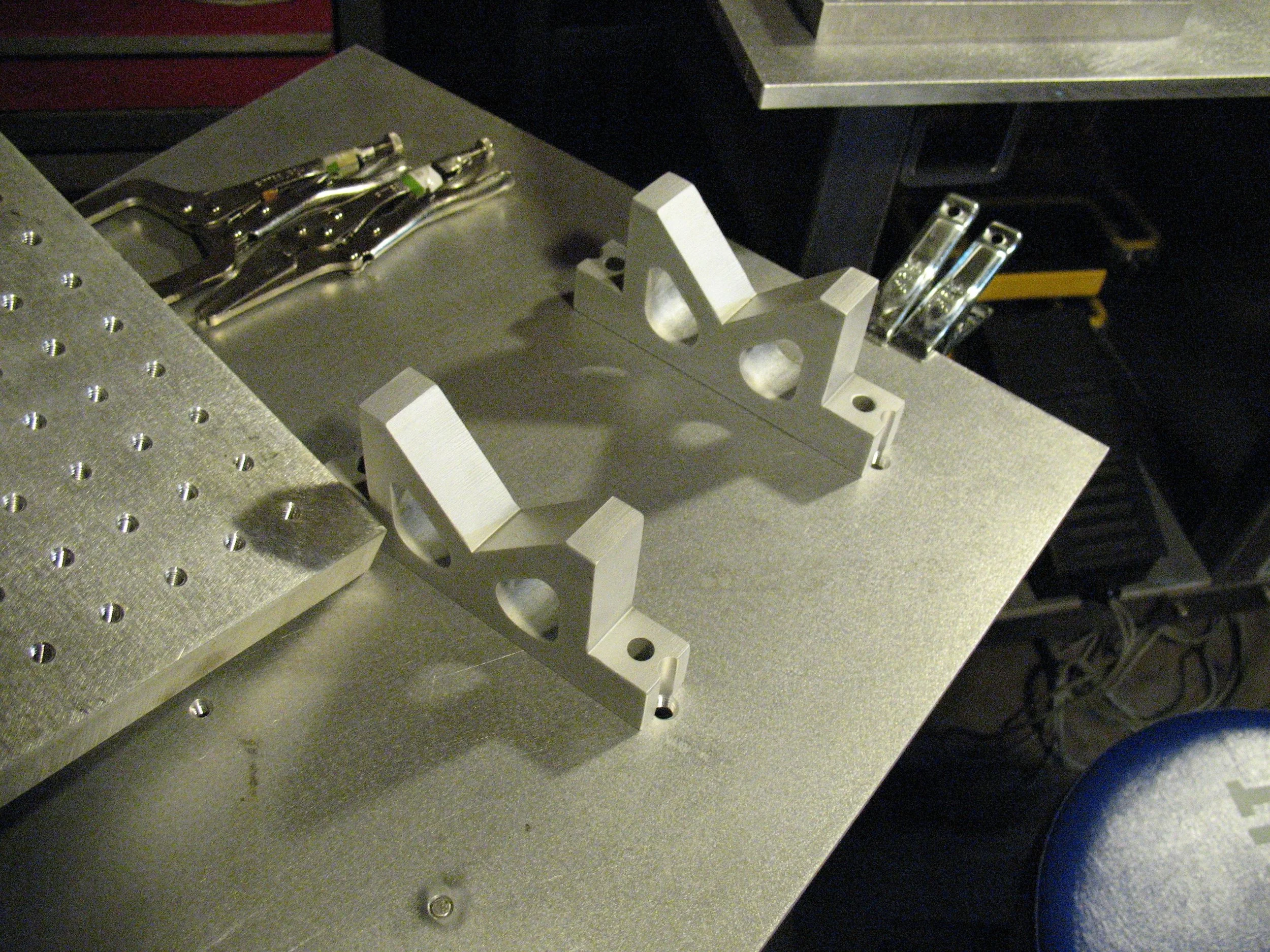

6

Titanium Irradiation Container

5

Nuclear Reactor Control Rod Guide Tube

28

Research Welding Projects

2

Vacuum Power Feed Thru

11

Surgery Tool Creation and Modification

13

TOOL BOX

4

Van Organization System

4

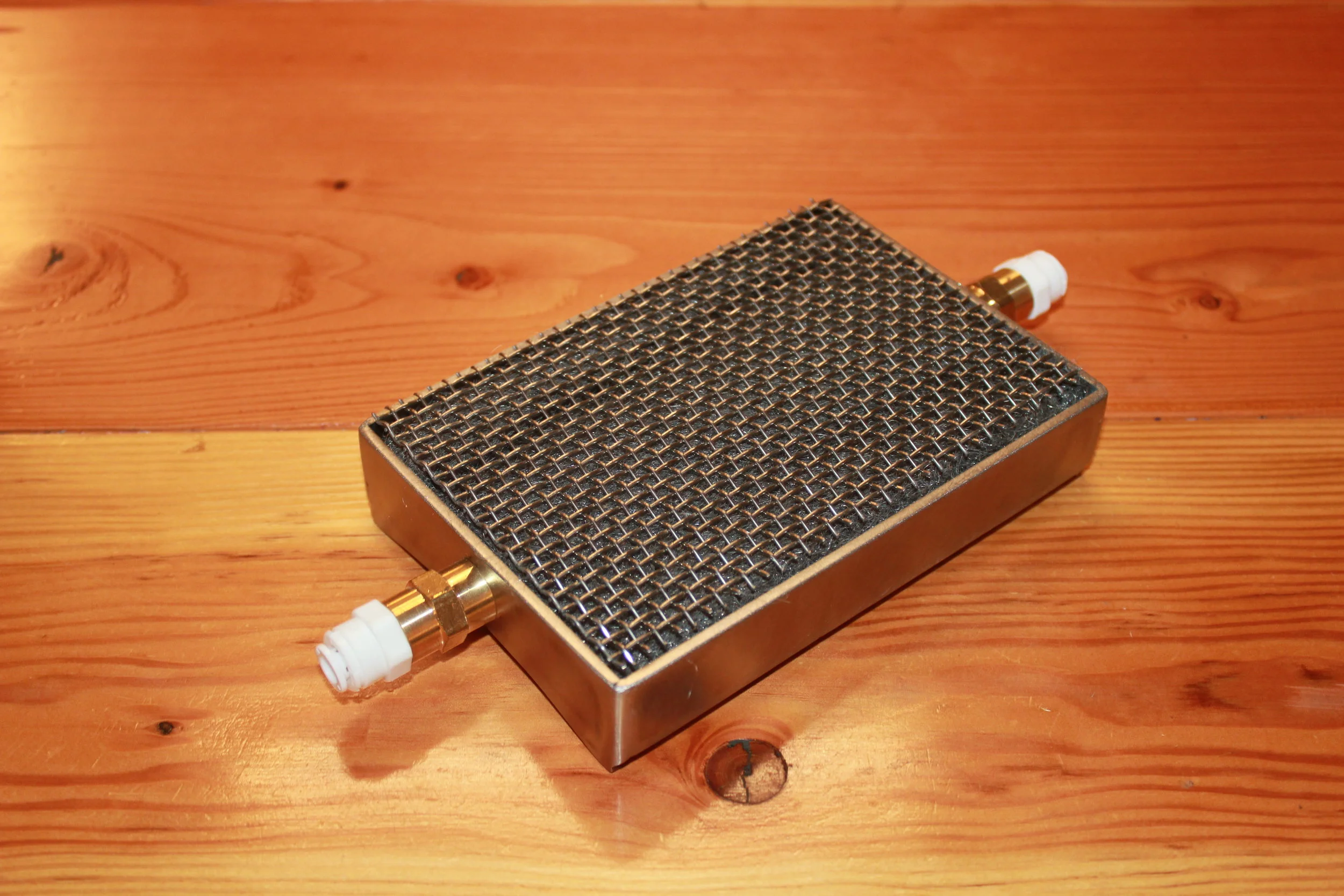

SS Gas Heating Forges

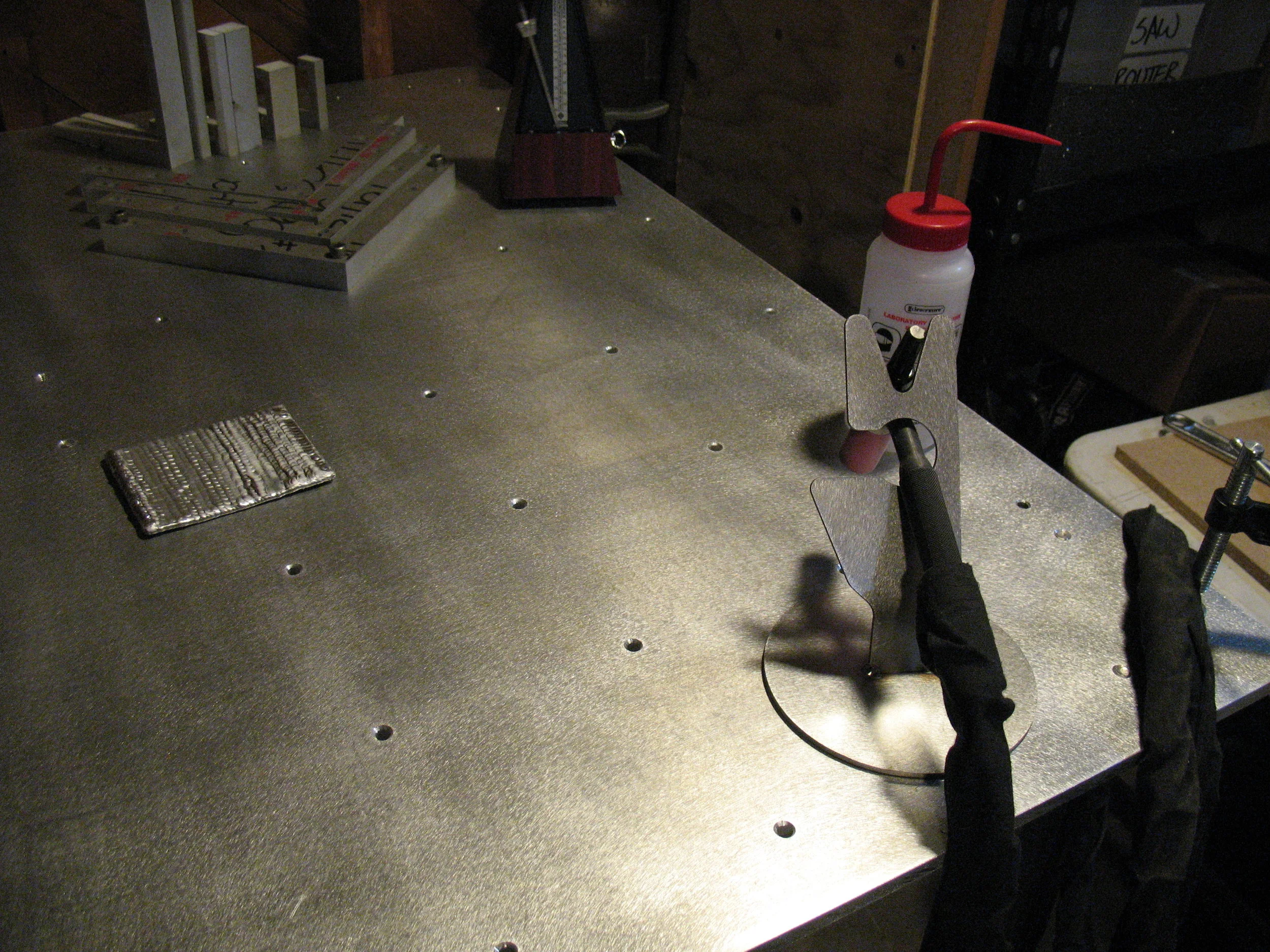

7

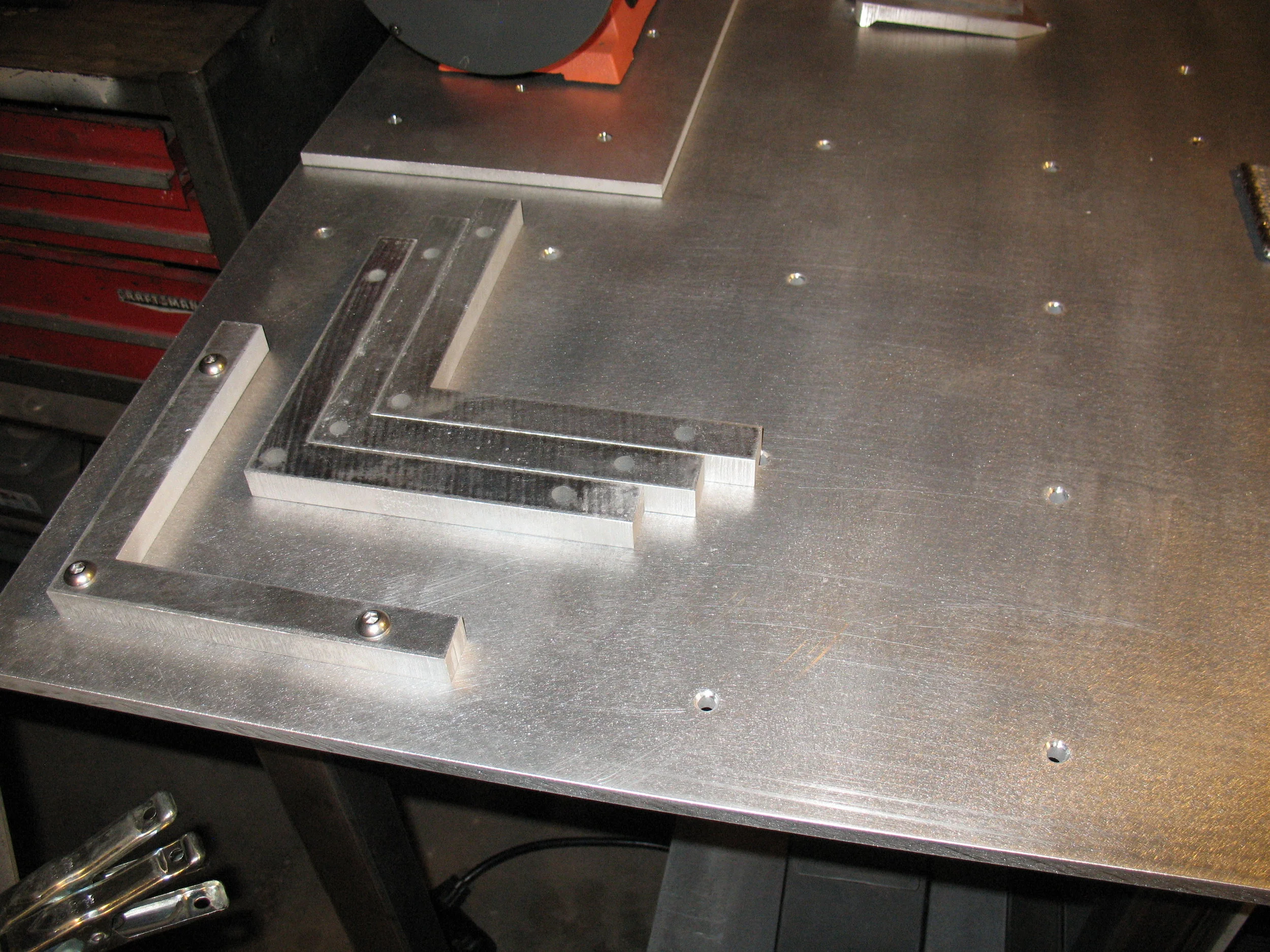

Welding Work Table

10

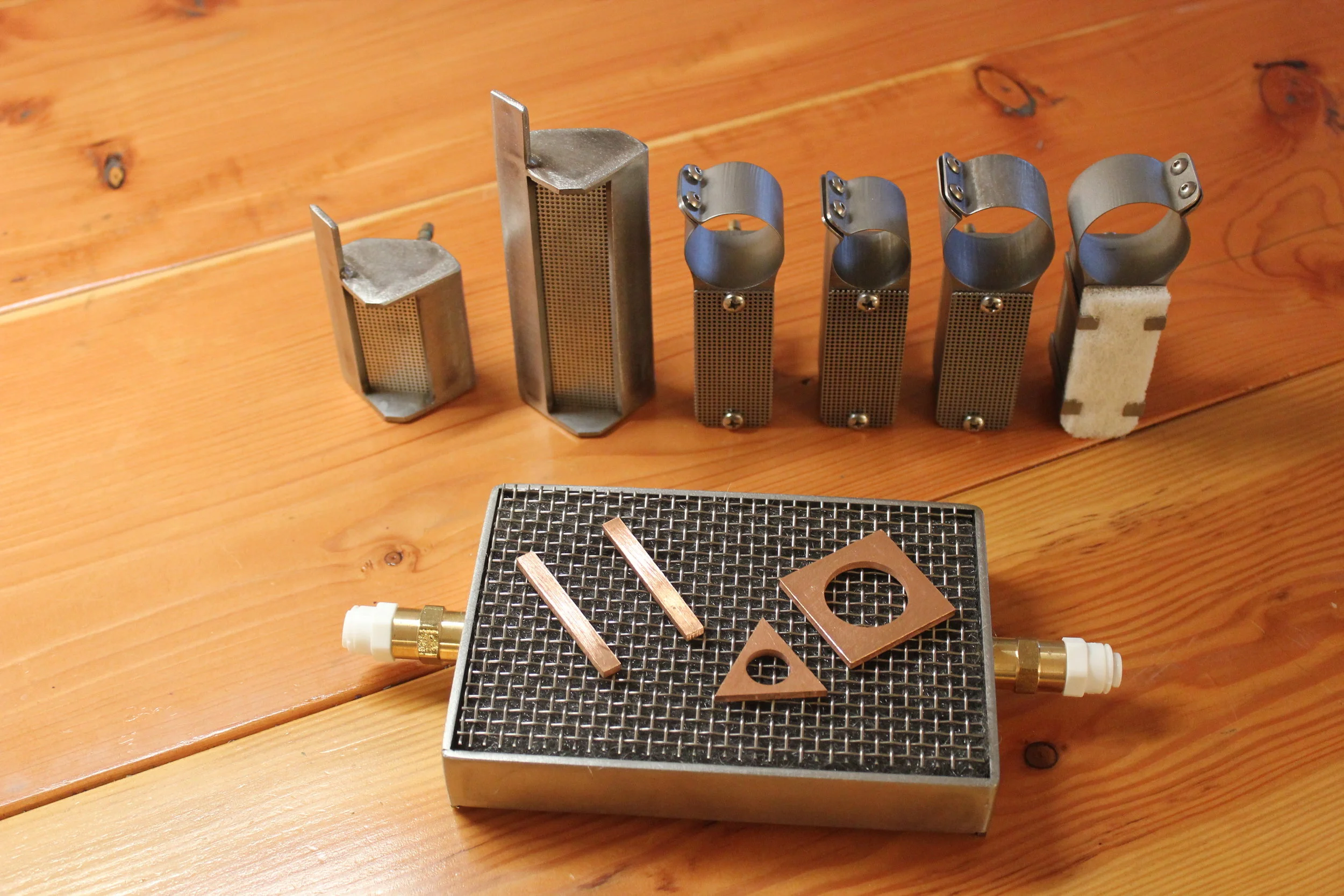

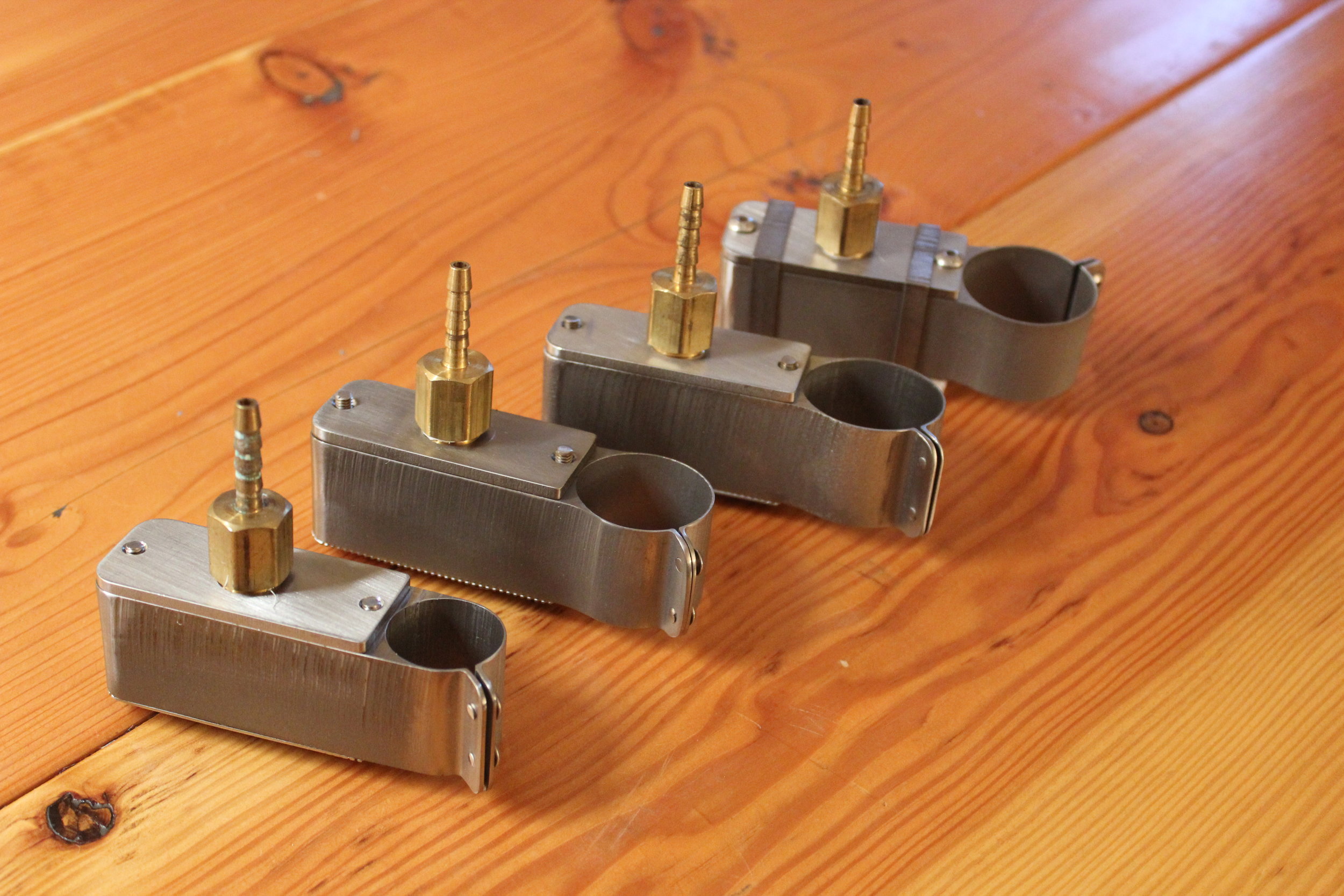

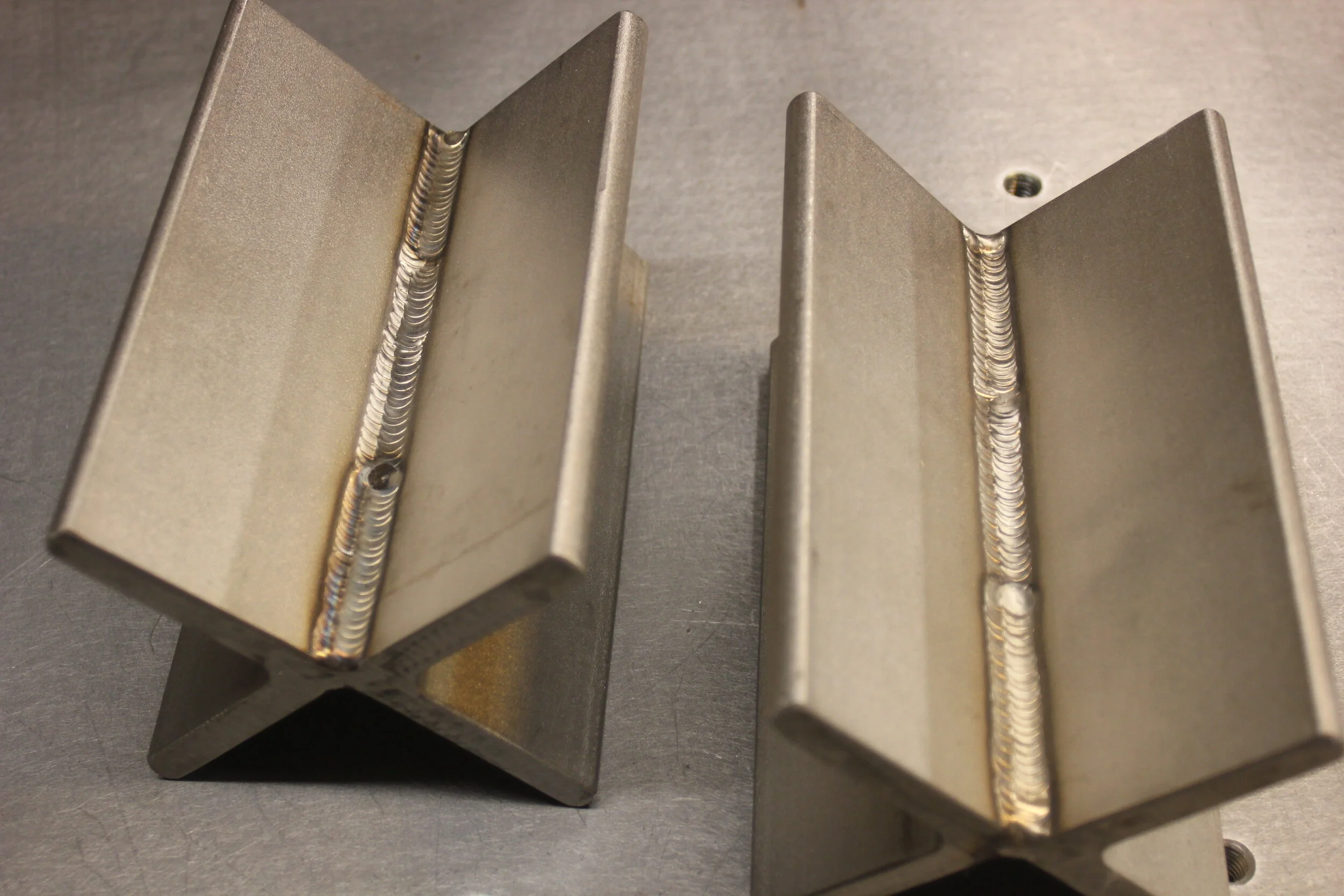

GTAW Auxiliary Shielding

9

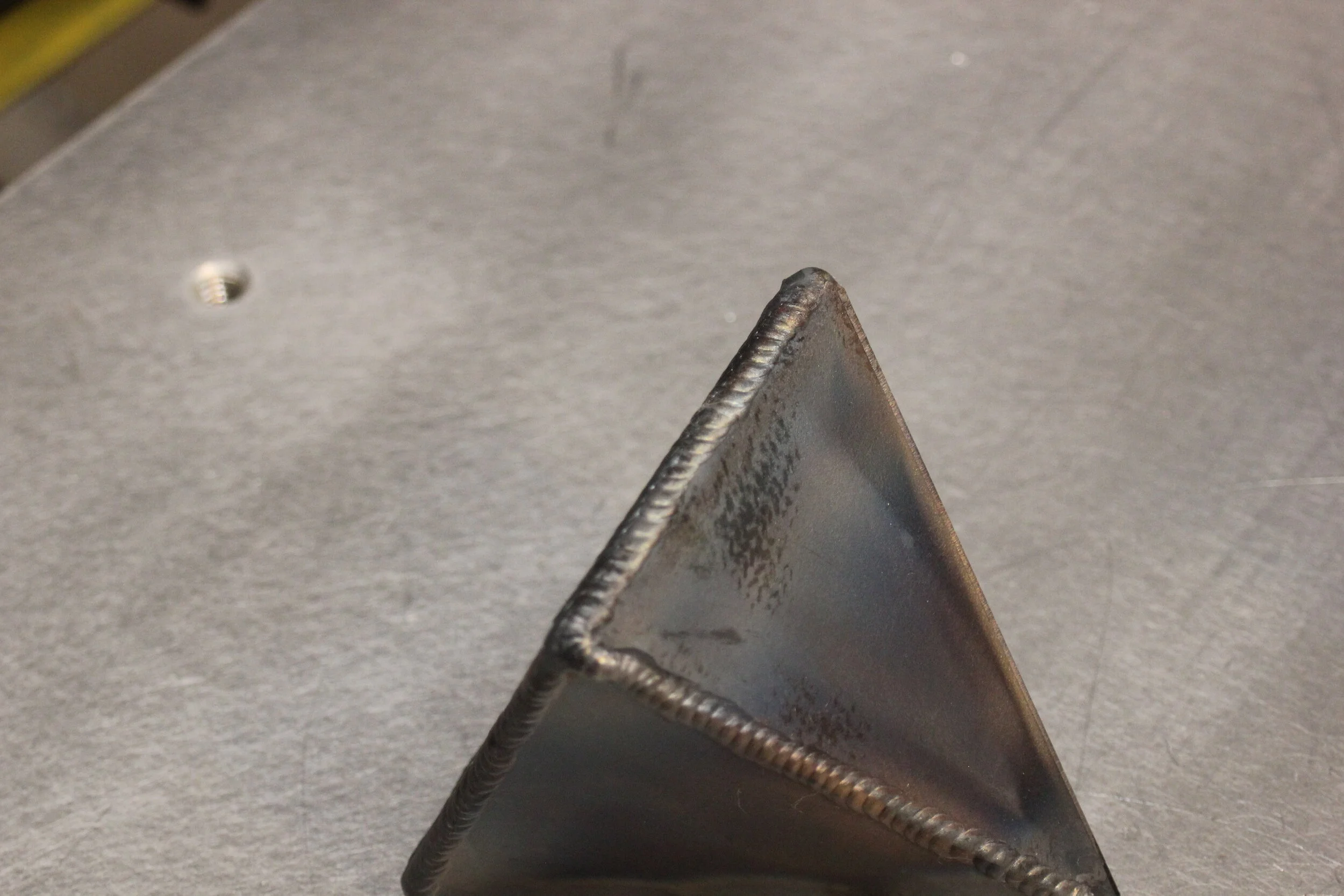

GTAW WELDS

10

Hammerton Lighting

3

Shop Stool

2

Anvil Stand